In fact, people have been constantly trying to explore some good methods and materials to repair and make up for some common defects of stone to improve the overall quality and effect of stone. This is particularly important in the large-scale production and application of stone today, just like people’s pursuit of beauty.

Of course, whether it is human beautification or the repair of stone defects, it is inseparable from the generation and application of some new technologies and new materials.

Only by bringing forth the old and bringing forth the new, and timely applying some scientific and reasonable new materials, can the effect of stone repair be more perfect, and this effect cannot be limited to the factory link, but also must be maintained in the installation and use links to maximize the comprehensive benefits.

Part.1 Waxing

Waxing the stone board surface is one of the earliest applications, the lowest cost, and the most commonly used method for some stone manufacturers to obtain better gloss and board surface effects. It can cover up some fine cracks on the board surface and increase the gloss and color of the stone.

However, this method and material cannot fundamentally solve the problem, and the effect is less durable.

If the waxed board is used outdoors, it will expose its original appearance in a short time. In addition, waxed stone is not breathable because the wax blocks the pores of the stone, which often leads to stone lesions and makes stone protection treatment difficult. Wax also absorbs dust, making the surface of the treated stone easily contaminated.

Part.2 Unsaturated resins are used for stone repair and enhancement

Some stones have natural cracks and holes, which makes the surface effect of the board poor and the breakage rate is high during processing and installation, especially for stone and some large-sized boards. Therefore, people introduce unsaturated resins into stone repair and enhancement.

The scientific name of the unsaturated resin we are talking about is unsaturated polyester resin. When the linear polymer compound formed by the condensation of saturated or unsaturated dibasic acid and saturated or unsaturated diol is dissolved in a monomer (usually styrene) to become a viscous liquid, we call it unsaturated polyester resin.

Unsaturated polyester resin is a thermosetting resin that can be cured into a high molecular network polymer under the action of heat or initiator. It is used in the repair and enhancement of stone based on the following aspects: fast solidification speed; low viscosity, easy to use and operate; light color, good transparency; high colloid hardness, good polishing; simple preparation, low cost.

1) Unsaturated resin for stone surface repair

The unsaturated resin is diluted to an appropriate viscosity, or suitable pigments and powder fillers are added to repair holes and cracks on the stone surface. At this time, we call it stone surface glue. This surface glue is mainly used for repairing cracks and defects on the surface of marble slabs during factory production and filling holes in travertine. When using, the entire board surface can be scraped with glue or partially repaired according to the defects of the board, and then placed naturally to solidify the colloid and then polished or heated by a device to make the colloid solidify quickly and then polished.

Based on the above points, people have used unsaturated resin for stone repair for a long time and have achieved satisfactory results. However, due to the shortcomings of unsaturated resin itself, it has some physical shortcomings as a stone repair material: poor adhesive strength of the colloid; high brittleness of the colloid; high shrinkage rate of the colloid; poor resistance to moisture and heat.

The specific manifestations on stone are: the cracks on the stone slab surface that are filled and bonded will break when subjected to force; the colloid used for filling will shrink after consolidation and grinding; the colloid and the stone joint will shrink and crack. Therefore, people continue to explore the use of some resin materials with more perfect performance for stone repair.

2) Unsaturated resin for stone reinforcement

Some crack-rich and loose stones (mainly marble), especially large-sized plates, are prone to breakage and damage during processing, transportation and installation, so people also use unsaturated resin for stone reinforcement. Applying glue and backing net on the back of stone is a common method used by some stone factories to prevent stone from breaking and damage. When using, the unsaturated resin is formulated into an appropriate viscosity, and then applied to the entire back of the stone, or a layer of fiber net is glued on it to achieve the purpose of reinforcement and support. At this time, we also call this unsaturated resin as stone backing glue.

Some disadvantages of unsaturated resin also make it have some problems as stone backing glue:

This backing glue is only applied on the surface of the stone without penetration effect, and will not strengthen the essence of the stone; it is also not suitable for the treatment of some low-strength and easily broken stones when producing thin plates; the adhesive layer has poor adhesion to the stone, and the plate is damaged after peeling; the adhesive layer has poor adhesion to the stone and poor moisture resistance. In the case of wet stone laying, the adhesive layer must be torn off, otherwise it will cause hollowing of the stone.

Comprehensively analyzing these problems, it is not difficult to see that the plates treated with this reinforcement material only play a certain role in the factory stage. During installation, if this layer of glue is torn off, the breakage rate of the plates is still very high.

3) Marble glue

When discussing unsaturated resin as a stone repair material, we cannot ignore marble glue, because this common stone repair material on the market is also prepared by unsaturated resin. In addition to the shortcomings of unsaturated resin, this marble glue has a large amount of solvents and fillers added during preparation, and the randomness of the curing agent addition makes its consolidation degree and bonding strength worse. What’s more terrible is that it is also used by some people to anchor the pendants when installing stone curtain walls. Of course, the reason why it attracts people to use it is not only convenient to use, but also cheap.

Part.3 Epoxy resin used in stone repair and reinforcement

In view of the shortcomings of unsaturated resin, it has many problems as a stone repair material, which prompts people to look for other materials to make the stone repair and reinforcement effect more perfect. With the continuous improvement of epoxy resin production technology and quality, and the continuous innovation of curing materials, it has become a relatively scientific and perfect material for stone repair and reinforcement.

Epoxy resin refers to an organic polymer compound containing two or more epoxy groups in the molecule, which is usually processed into liquid resin for use. Because the molecular structure contains active epoxy groups, they can react with various types of curing agents to form a polymer with a three-dimensional network structure. It is used in stone repair and reinforcement based on the following aspects: good physical properties, high bonding strength; relatively low colloid curing shrinkage; large controllability of curing time, can be cured at room temperature or high temperature; appropriate molecular weight, adjustable viscosity, good wettability and permeability; relatively low shrinkage when the colloid is cured.

1) Epoxy resin for stone surface repair

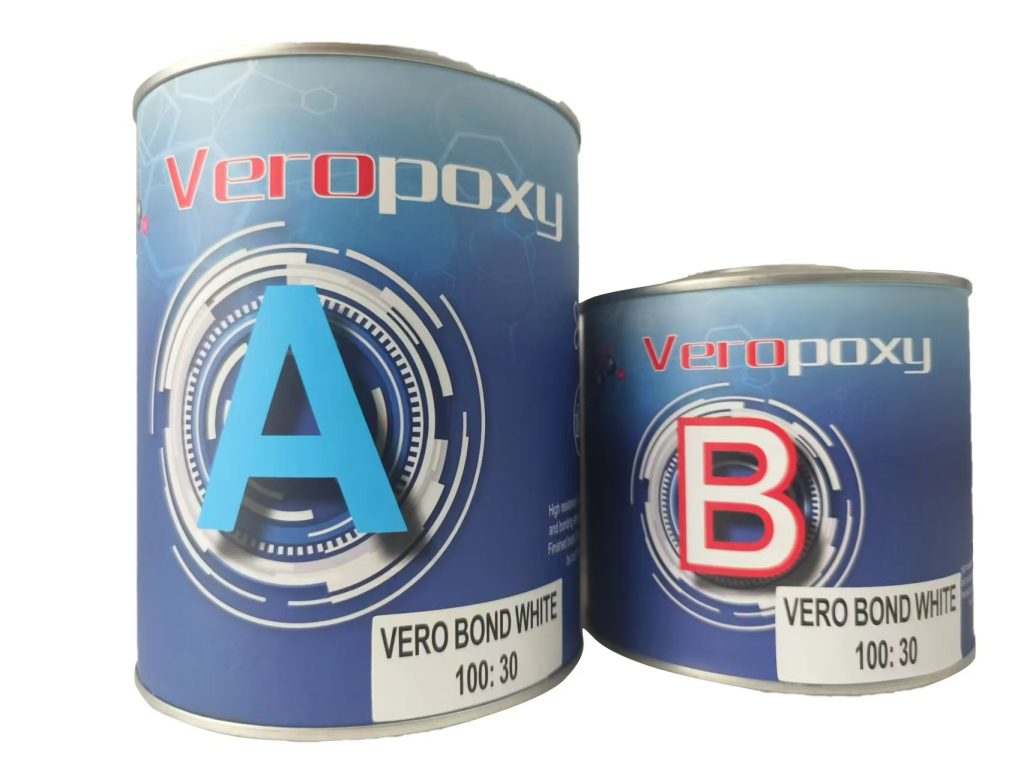

Select appropriate epoxy resin and curing agent, or add pigments and fillers to the epoxy resin in advance, and mix them in the form of A and B components in a certain proportion to repair holes and cracks on the stone surface, so it can also be called stone surface glue. Usually, this kind of surface glue is also mainly used for repairing cracks on the surface of granite during factory production, repairing cracks and defects on the surface of marble slabs, and filling holes in travertine. When using, the entire board surface can be scraped with glue or partially repaired according to the defects of the board, and then placed naturally to solidify the colloid and then polished or heated by a device to make the colloid solidify quickly and then polished.

Epoxy resin has more advantages as a stone surface glue than unsaturated resin; it has high bonding strength and the bonding part is not easy to crack; it has good permeability and can penetrate into the cracks to make up for the bonding; the colloid shrinkage rate is low, and the glue surface will not sink after polishing; it can repair the common small cracks on granite. Epoxy resin is replacing unsaturated resin as a stone repair material with an increasing trend.

2) Epoxy resin is used for stone reinforcement

Since epoxy resin has good bonding strength, permeability and moisture resistance, it can also be used as an ideal stone reinforcement material for scraping on the back of the stone to prevent the stone from breaking and breaking. Epoxy resin is used as stone backing glue, which has the following advantages compared with unsaturated resin stone backing glue: the colloid has a certain permeability and can enter the cracks for bonding and repair; the colloid has excellent bonding strength with the stone surface, and the glue layer and the backing net will not peel off; because the bonding strength between the glue layer and the board is high, the backing glue and the backing net do not need to be torn off during paving, and the breakage rate of the board is relatively reduced.

However, although epoxy resin has many advantages as a stone repair material, it still has some shortcomings: the curing time of the colloid is relatively long; the AB group ratio is relatively strict; the existing drying equipment needs to be modified during assembly line operation, because many of the earlier glue repair lines were designed according to unsaturated resin; the cost of use is higher than that of unsaturated resin. In response to these problems, our material manufacturers are also actively exploring to solve some contradictions between the curing time and application effect of epoxy resin. Some factories have also modified their equipment to adapt to the large-scale application of epoxy resin.

Despite this, epoxy resin can still be promoted as an ideal stone repair and reinforcement material. Now, most stone dealers in Europe have adopted epoxy materials and processes to repair and reinforce large areas of stone, and it can also meet the physical requirements for reinforcement materials in some stone-related standards.

Post time: 11 月-05-2024