Imagine a majestic granite countertop, beautifully veined and undeniably strong, yet needing a little extra help to withstand the rigors of daily use. Although Granite is known for its durability, even this strong natural stone can gain from a strength boost—especially in demanding surroundings. Now let me introduce epoxy resin, a substance praised for its outstanding bonding and strength. Can it, however, really strengthen granite and make it even more tough? Let’s explore this amazing synergy between granite and epoxy resin and see how this dynamic team might support one of the toughest rocks found in nature.

The Natural Strength of Granite

Granite, formed under intense geological pressure, is renowned for its robustness and durability. From kitchen counters to outdoor sculptures and major constructions, it is extensively used in building. Granite does, however, have microscopic flaws and micro-cracks, which, although not always apparent, over time can compromise its general structural integrity particularly in highly stressed environments. This is where epoxy resin comes in: it helps to improve the natural toughness of the granite by filling in these minute defects.

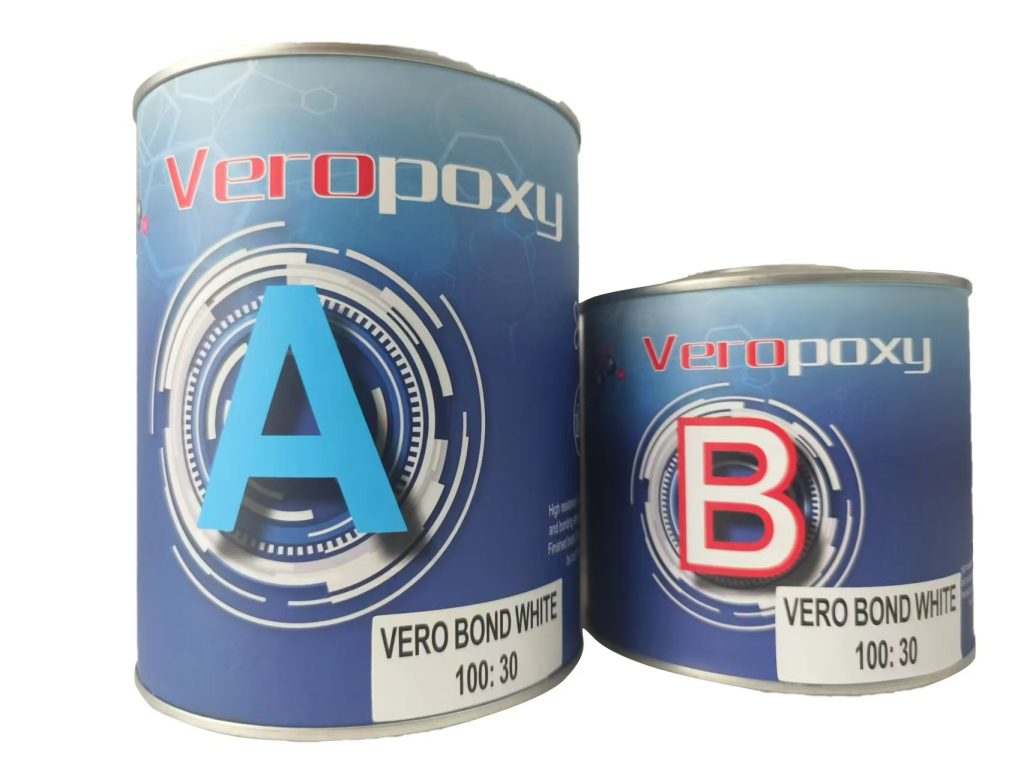

Epoxy Resin’s Bonding Power

Epoxy resin is a versatile adhesive known for its remarkable bonding ability. It is especially suited for natural stones like granite since it follows porous surfaces rather strongly. Applied to granite, epoxy resin fills the small fissures, pores, and cracks, so strengthening and harmonising the surface. This bonding action not only strengthens the granite but also stops these small defects from developing into more significant, maybe destructive cracks.

How Epoxy Resin Enhances Granite’s Strength

Filling Micro-Cracks and Fissures

Over time, even the toughest granite surfaces can develop microscopic cracks due to environmental stress, such as temperature changes, moisture, and impact. Applied to granite, epoxy resin fues with the stone and fills in these micro-cracks. Epoxy resin can drastically lower the possibility of additional damage by closing these weak areas, so strengthening the granite.

Preventing Water Penetration

Granite is naturally somewhat porous, allowing water to seep in, especially through its surface fissures. Moisture entering the stone might compromise its internal strength. Even in damp or humid conditions, epoxy resin serves as a water-resistant barrier that keeps moisture from seeping in and so preserves the structural integrity of granite.

Resistance to Thermal Stress

Granite can crack under extreme thermal stress, such as when exposed to high temperatures or drastic temperature changes. When applied as a coating, epoxy resin offers a layer of protection that absorbs and distributes heat, so enabling the granite to resist temperature variations without cracking. This is particularly helpful in outdoor installations subject to the elements or in kitchen uses.

Enhanced Impact Resistance

Although granite is hard, it can still chip or crack under significant impact. Acting as a surface coating or bonding agent, epoxy resin increases granite’s impact resistance. Epoxy lessens the possibility of chipping or other obvious damage from inadvertent drops or pressure by strengthening the surface and inner micro-structure.

Increasing Load-Bearing Capacity

The addition of epoxy resin can improve the load-bearing capabilities of granite slabs. For counters and flooring in industrial or commercial kitchens, for example, which often support heavy loads, this extra reinforcement helps. The epoxy strengthens the granite’s structure so it may carry more weight without sacrificing its integrity.

Application Techniques for Optimal Strength

Achieving the best strength-enhancing effects of epoxy resin on granite depends on proper application methods. The surface has to be painstakingly cleaned, free of oils and dust, so enabling the epoxy resin to stick completely. Sometimes methods like vacuum impregnation—epoxy is injected into the granite under a vacuum to guarantee it reaches deeply into the stone’s pores—are used. Correct curing is equally crucial; the resin must set under controlled conditions to create a strong bond capable of handling the stress and strain granite faces over time.

Limitations and Considerations

While epoxy resin significantly enhances granite’s strength, it’s not a cure-all. Epoxy should be applied very carefully to prevent air bubbles from being trapped and so weaken the bonding. Moreover, too high levels of epoxy might change the natural texture and look of granite. Unsuitable application or overuse can produce an artificial or too glossy surface. Therefore, working with experienced professionals for optimal results is essential.

Environmental Impact and Durability

Epoxy resin has come a long way in terms of environmental friendliness. Many modern formulations are designed to be low-VOC (volatile organic compounds) and non-toxic once cured, making them safer for indoor use. When applied correctly, epoxy resin significantly extends the life of granite surfaces, reducing the need for repairs or replacements and thereby minimizing waste. This durability is particularly beneficial in high-use environments, where the granite’s longevity is essential.

In the partnership between granite and epoxy resin, we find a powerful alliance. Epoxy resin doesn’t just offer a superficial shine but genuinely strengthens and reinforces granite, transforming it into an even more resilient material. From filling micro-cracks to resisting impact and water, epoxy resin proves to be a versatile tool in enhancing granite’s natural strength. By bridging the gap between nature’s beauty and modern technology, epoxy resin is allowing granite to stand the test of time—stronger and more stunning than ever before.

Post time: 11 月-06-2024