Epoxy resin has emerged as a go-to adhesive for bonding stone materials due to its strong, durable, and visually seamless properties. From opulent marble counters to sturdy outdoor granite installations, the lifetime of the epoxy-stone bond determines the success of these uses. But when bonded to stone, how do we really find out if epoxy resin will last? The solution is durability testing, which models several environmental conditions to know how epoxy performs in practical settings. This research will explore some creative and thorough techniques applied to test the durability of epoxy resin bonded to stone, so exposing understanding of the science behind these strong bonds.

Common Durability Challenges in Epoxy-Stone Bonding

Stone surfaces come with inherent challenges, such as porosity, texture, and natural fissures, which can impact bonding effectiveness. Especially in outdoor or high-traffic settings, the epoxy bond suffers extra stresses from temperature fluctuations, moisture exposure, chemical interactions, and UV radiation. Therefore, durability testing has to cover a broad spectrum of elements to replicate actual conditions.

Understanding how epoxy resin holds up against these variables not only assures the longevity of stone applications but also helps manufacturers improve formulations. Testing the resilience of the epoxy-stone bond will help us to guarantee that architectural and decorative stone features retain over time both beauty and utility.

Key Durability Testing Methods

1.Thermal Cycling Tests

Temperature fluctuations can cause stone and epoxy to expand and contract, potentially weakening the bond over time. Samples in thermal cycling tests are subjected to repeated cycles of heating and cooling, so mimicking conditions such as seasonal fluctuations or day-night temperature changes. This test guarantees that the epoxy-stone bond can resist expansion and contraction without cracking or delaminating, so helping to evaluate its elasticity and resilience.

2.Moisture Resistance Tests

For stone surfaces used in areas with high humidity, moisture resistance is critical. Epoxy-bonded stone samples are submerged in water or under controlled humidity settings for long lengths in moisture resistance tests. The aim is to find whether extended water contact weakens, swells, or breaks the bond. Applications including bathrooms, kitchens, and outside spaces depend on moisture-resistant epoxies.

3.Chemical Exposure Tests

From food’s acidic compounds to cleaning agents, stone surfaces come into frequent contact with many chemicals. Applying either acidic or alkaline solutions to the epoxy bond, chemical exposure tests track any evidence of degradation, discolouration, or bond weakening. Kitchen counters and labs, where chemical spills are common, depend especially on this test.

4.UV Light Exposure Tests

UV stability is a major consideration for outdoor stone projects since extended sunlight can yellow or degrade epoxy. Samples used in UV light exposure tests are continuously UV-radiated to replicate months or years of sun exposure. Examining any variations in colour, strength, or bonding quality helps this test determine whether the epoxy resin can meet outdoor needs.

5.Load-Bearing and Shear Strength Tests

Stone uses, including counters, flooring, or stairs, bear continuous weight and pressure. Load-bearing and shear strength tests gauges the bond’s capacity to resist force and weight over time. Under these tests, controlled weights or mechanical forces are applied to epoxy-bonded stone samples until the bond fails. Essential information on the weight or impact the bond can bear before breaking comes from this testing.

6. Freeze-Thaw Cycling

Freeze-thaw cycles can especially damage stones in cold climates. Frozen water expands, possibly upsetting the bond. Epoxy-bonded stone is frozen and thawed repeatedly in freeze-thaw cycling to evaluate whether the bond can withstand this stress without weakening or cracking. Stone applications in outdoor settings prone to frost and snow depend critically on this test.

7. Abrasion and Impact Testing

Stone surfaces in busy places like flooring or public monuments have to withstand foot traffic, impacts, and scratches. By forcing the epoxy bond to mechanical wear and shocks, abrasion and impact tests replicate these stresses. This test finds whether the bond can keep integrity even under constant physical strain.

8.Aging and Weathering Simulations

Tests on ageing and weathering expose epoxy-stone samples to several environmental elements over extended times. Samples might be kept in outdoor settings or manmade environments mimicking sun, rain, wind, and changing temperatures. This all-encompassing test provides a reasonable estimate of the epoxy bond’s longevity under years of exposure.

Practical Considerations in Durability Testing

Epoxy on stone durability testing uses simulated extreme conditions to find the bond’s limitations. Real-world applications, however, might call for a mix of elements at reasonable levels instead of ongoing intense stress. For the particular application, then, selecting the appropriate epoxy formulation is absolutely crucial. For outdoor marble sculptures, for instance, high UV resistance is necessary; for granite countertops in kitchens, moisture resistance is quite important.

Additionally, proper application techniques such as surface preparation, curing time, and temperature control during installation can impact the durability of the epoxy bond. Testing guarantees the bond is not only chemically stable but also properly applied, so providing information for optimising these variables.

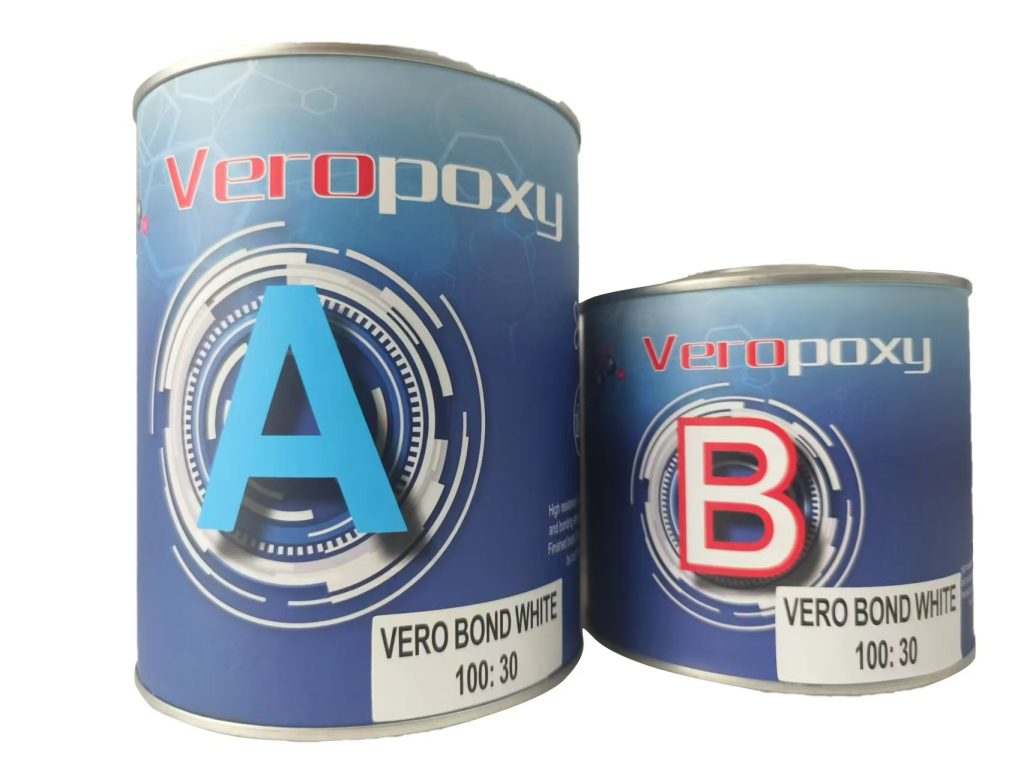

Epoxy resin

Epoxy resin has proven itself as a reliable adhesive in the stone industry, providing a seamless and resilient bond that can endure environmental stresses—if chosen and applied correctly. Understanding the limits and strengths of epoxy when bonding to different stone types depends on durability testing, which also helps builders and manufacturers choose the correct materials for the job. Epoxy-bonded stone surfaces will remain beautiful and structurally sound for years to come if we carefully test for elements including temperature, moisture, UV light, and abrasion. In the field of stone restoration and design, epoxy’s versatility makes it a pillar of contemporary masonry.

Post time: 11 月-06-2024