In the world of construction and interior design, natural stone materials such as marble, granite, and onyx bring beauty and timeless appeal. Some stones, though, are naturally brittle and need for careful strengthening methods. Reinforcing these materials is much aided by epoxy resin, whose exceptional adhesive qualities and adaptability help. With epoxy resin taking front stage, let us explore two main techniques for strengthening stone: “back mesh” reinforcement and surface penetration reinforcement.

The Need for Stone Reinforcement

Due to their natural formation, stones often contain microcracks, pores, and other imperfections that may compromise their strength, particularly during transportation, installation, or polishing. Reinforcement methods assist to increase the resilience and durability of delicate stones more likely to be damaged. Since epoxy resin adheres well to different types of stone, it provides the perfect solution since it builds a fortified construction able to manage more stress.

Back Mesh Reinforcement

What Is Back Mesh Reinforcement?

Back mesh reinforcement is a process where a strong fiberglass or synthetic mesh, usually with 5x5mm grid patterns, is bonded to the back of the stone using epoxy resin. This network preserves the natural beauty of the stone and strengthens it so enhancing its lifetime. Usually ranging in width between 1.2 and 1.8 meters, rolls of fiber mesh weigh around 900g/m².

This method is particularly suitable for large slabs and thin panels of marble, granite, travertine, and onyx, among others. Acting as a binding agent, the epoxy resin gives the stone longevity without adding undue weight.

Epoxy Resin in Back Mesh Reinforcement

Epoxy resin used for back mesh reinforcement is a low-viscosity adhesive that ensures easy application. It takes about six to nine hours to cure under normal temperatures; but, the curing time can be greatly shortened if an oven is used for heating. A component of the adhesive can be heated up to improve workability in colder surroundings, so thinning the resin and accelerating the curing process.

For optimal results, the curing temperature should ideally be between 25°C and 75°C. Pre-heating the environment or stone itself increases the bonding strength and quality of the resin in colder months, so producing a more effective reinforcement.

Factors Affecting Cure Time

The curing time for back mesh reinforcement varies based on the stone type, production volume, and available curing equipment. While smaller production lines can depend on hand application with natural curing at ambient temperatures, high-output production lines may gain from automated mesh application using horizontal or vertical curing ovens. Natural curing advised for a 24-hour cure period will help the resin to completely harden before next processing.

Surface Penetration Reinforcement

The Challenge of Surface Cracks

Sometimes stones have surface cracks and fissures that might run far into the material. The stone can lack the required strength for handling or finishing even with back mesh reinforcement. Surface penetration reinforcement fills and bonds surface cracks allowing an epoxy resin to seep into them, so enhancing overall strength.

Application of Epoxy Resin for Surface Reinforcement

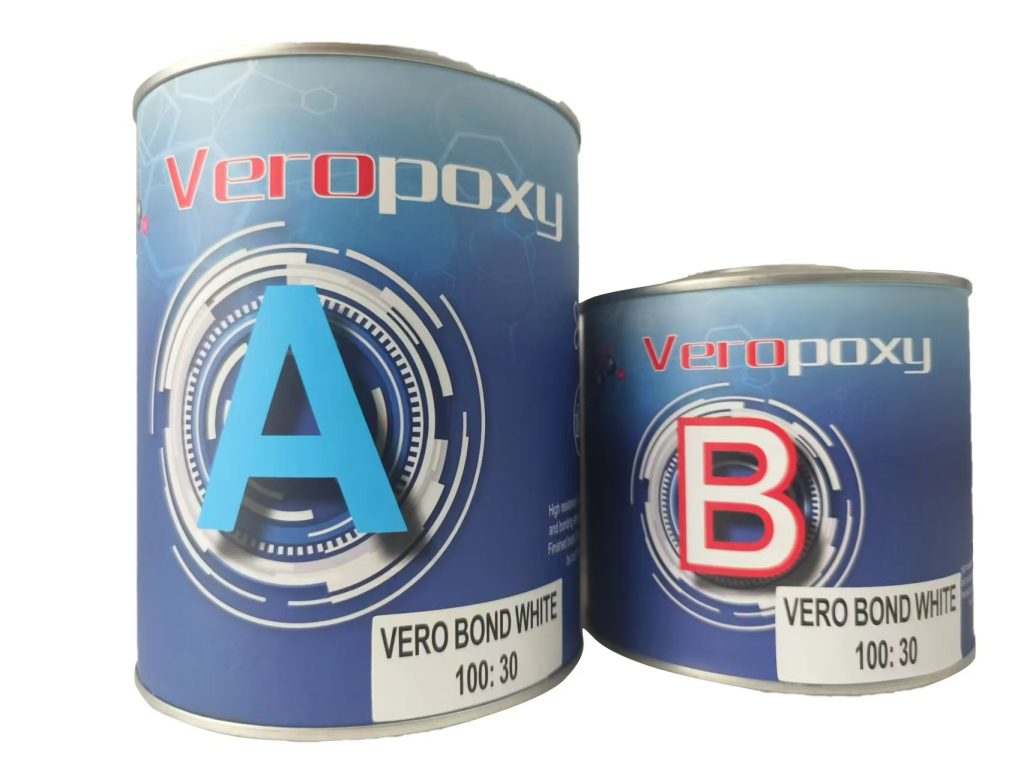

Surface penetration reinforcement involves applying a high-strength epoxy resin (often a two-part AB adhesive) to the stone surface. Resin binds within the stone, penetrating cavities and fractures. The stone is fit for polishing, finishing, and other operations once it has been applied since heat curing completely solidifies the resin. Horizontal or vertical ovens are used in high-production environments to accelerate the curing process, so guaranteeing strong resin bonds. Smaller production lines should allow a 24-hour cure for best reinforcement even though ambient curing may be used.

Color Matching Epoxy Resin for Aesthetic Appeal

Surface reinforcement is done on the visible surface of the stone, thus it’s crucial to match the color of the resin with the stone’s look. Usually added to the resin, color-matching pigment pastes guarantee flawless blending with the stone, so reducing any apparent residue. By using epoxy-compatible colorants, resin curing is not interfered with, so guaranteeing both functionality and visual consistency.

Epoxy Resin: The Future of Stone Reinforcement

Epoxy resin has transformed the world of stone reinforcement. Not only is it robust and flexible but it can also be adjusted to fit varying curing conditions and times. Epoxy formulations keep becoming better as technology develops, giving more choices to increase stone resilience without compromising appearance. Epoxy resin has become a necessary friend in maintaining the beauty and lifetime of natural stone whether strengthening a delicate onyx slab or fixing minor cracks in marble.

Post time: 11 月-05-2024