Marble is the first choice for flooring materials due to its elegance and durability. However, the hollowing problem of marble floors often troubles homeowners, which not only affects the appearance, but also concerns safety. Traditional repair methods are time-consuming and labor-intensive, and the results are difficult to guarantee. This article will reveal a revolutionary solution for you – epoxy resin technology. With its excellent bonding performance and easy operation, it provides an efficient, environmentally friendly and economical repair method for the hollowing problem of marble floors. Next, let’s explore how epoxy resin can become a powerful tool to solve the hollowing problem of marble floors, so that your home can restore its former glory and safety.

What is a hollow drum?

What is hollow drums? After the wet-paste installation of floor stone care, there are gaps between the stone and the bonding layer, or the bonding layer and the base layer. A drum-like sound can be heard when tapping gently, so it is often called the hollow drum phenomenon of floor stone.

Why does marble have hollow drums?

1. Poor installation technology

Situation 1: When paving, the cement, mortar or adhesive on the back of the board is too thin. After paving, the water evaporates, and a gap is formed between the adhesive and the stone, causing hollow drums.

Situation 2: Instead of applying cement on the back of the stone, the worker directly pours the cement on the ground, smoothes it with a scraper, and then compacts the stone. When the cement is poured on the ground, the base layer will be washed away, resulting in uneven distribution, which will eventually make the bonding force uneven and form hollow drums.

Situation 3: When paving, when the work is finished, the stone on the edge of the paved area is not sealed. Cement spillage and rapid drying in the wind will cause hollowing.

2. Insufficient curing period for paving

After paving, various adhesive materials are still in the curing period of solidification. If you rush to cross-construct or put them into use in advance, the stone will easily loosen and form hollows.

Solution to marble hollowing

1. Remove the hollow marble slab and reinstall it. This method is more troublesome to construct and the repair cost is high. More importantly, it is difficult to make the gloss, color and pattern of the new and old marble slabs consistent after repair. If it is a large area of hollowing, this method wastes time and increases costs. It is recommended to use the second method.

2. Adopt the epoxy resin steel bolt anchoring method. The surface is firm after repair and will not be damaged. The construction method is simple, saving labor and materials.

Basic operation steps: detect hollowing and mark-drilling positioning-permeability test-temporary sealing of board seams-pressurized grouting-cleaning-repair-maintenance.

Hollow stone floor care method

Use epoxy resin steel bolt anchoring method. After repair, the base is strong and intact, and the construction method is simple, saving labor and materials. The construction steps are:

(1) For the hollow stone that needs to be repaired, determine the drilling position and number, and first use an electric drill with a carbide insert drill bit to drill a 5mm fine hole. It should be noted that the drill bit should be tilted downward at a 15-degree angle when drilling to prevent the epoxy resin slurry from flowing out of the hole after grouting. After the hole is drilled, the dust in the hole is removed with an air compressor. The dust removal air machine should be inserted to the bottom of the hole so that all dust can escape from the hole with the compressed air.

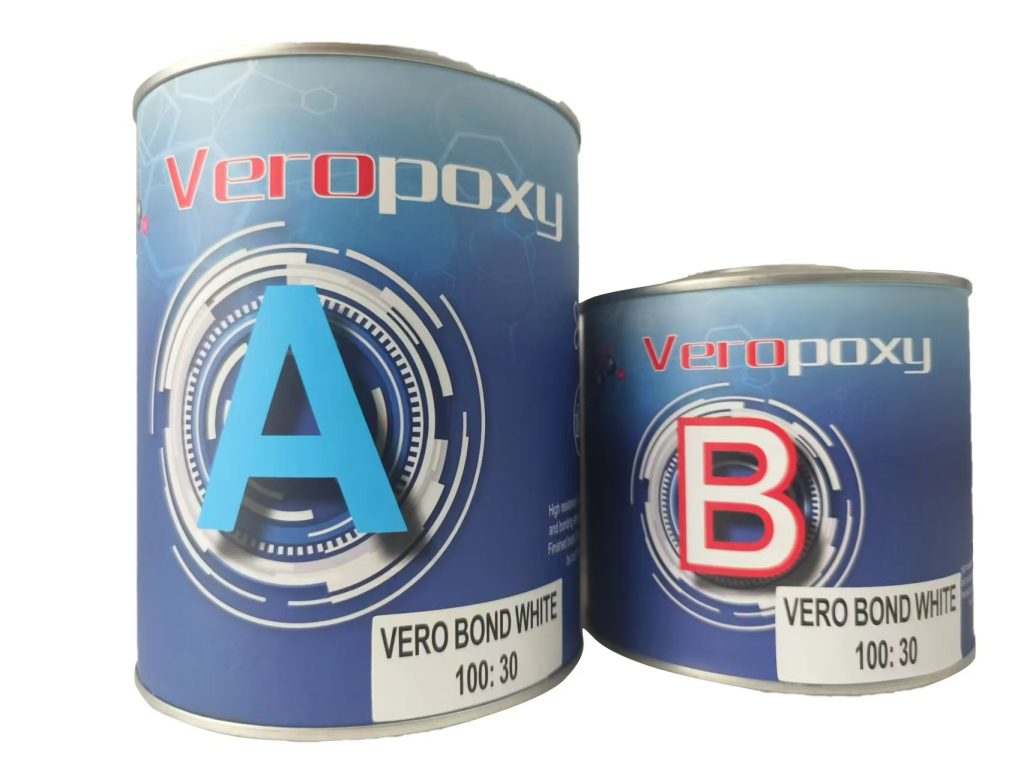

(2) Secondly, make epoxy resin slurry. Use epoxy resin, dibutyl phthalate, curing agent, and cement according to the appropriate proportion given in the stone care. When mixing, first mix the epoxy resin and dibutyl phthalate, then add the curing agent to mix, and then add the cement and mix well. Pour it into the grouting machine and it can be used.

(3) The next step is grouting and anchoring. Use a resin grouting gun to fill the hole with resin slurry. The gun head should be deeply inserted into the bottom of the hole and the gun head should be gradually withdrawn outward during grouting. After the slurry is filled, put in the steel anchor bolt. In order to improve the bonding effect, the bolt should be made into a threaded type and a hexagonal nut should be screwed on one end to firmly stick the marble slab.

(4) Before putting in the bolt, in order to prevent the injected epoxy resin slurry from flowing out and contaminating the marble surface, you can first use lime paste to block the hole. After the epoxy resin slurry solidifies, clean the plug. Then use acetone or xylene to clean the resin slurry remaining on the stone surface in time to avoid staining the floor.

(5) After grouting for two to three hours, seal with white cement mortar. The color of the color mortar should be as close as possible to the color of the stone surface being repaired. After completing the hollow stone care construction, wait for about a day for the epoxy resin slurry on the surface to dry, and then you can play with it happily again.

Post time: 11 月-05-2024