Quartzite, known for its remarkable strength and aesthetic appeal, is a favorite choice for countertops, flooring, and other high-impact surfaces. Even the toughest natural stones, though, are not impervious to damage. Now enter epoxy resin, a substance that has revolutionised our ability to improve the lifetime of quartzite surfaces. Quartzite gains much more resilience from epoxy resin filling it, which greatly raises its abrasion resistance. This combination of epoxy and quartzite is a match that enhances the durability of the stone while maintaining its beauty and provides a sensible but elegant answer for areas with lots of foot traffic or heavy use. We will discuss in this post how epoxy resin increases the abrasion resistance of quartzite, the science underlying this effective mix, and the reasons why it is becoming a preferred choice in demanding surroundings.

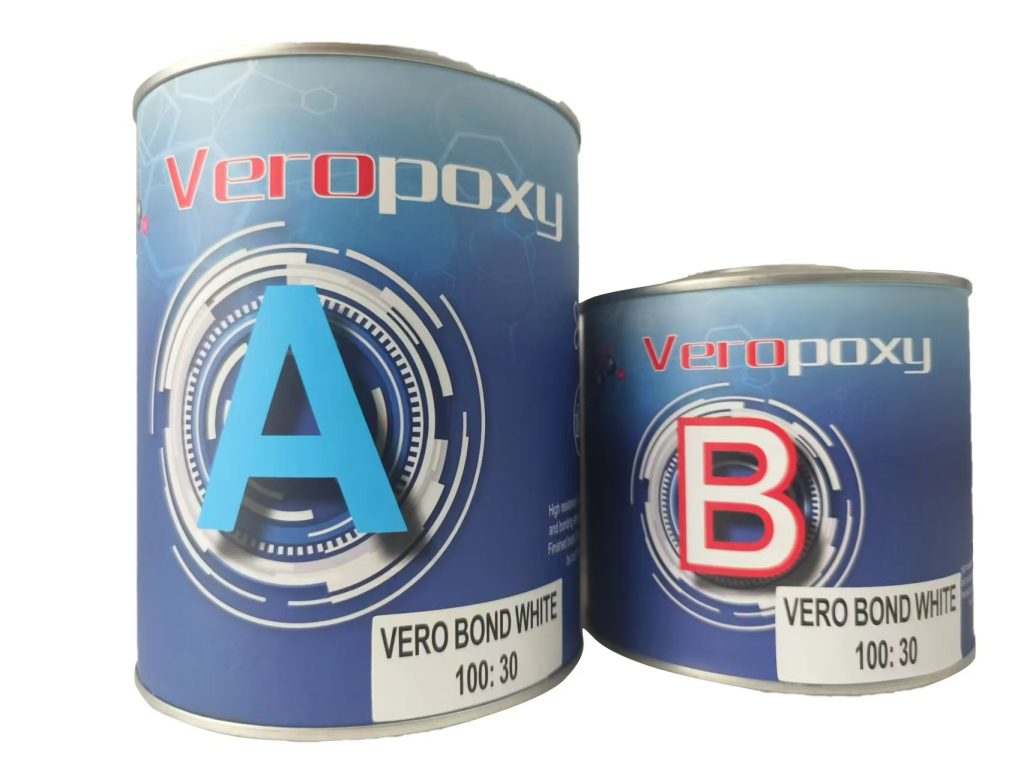

Epoxy resin

What is Epoxy-Filled Quartzite and Why is it So Durable?

Using epoxy resin, a flexible synthetic polymer, as a filler in quartzite will help to strengthen the stone and improve its abrasion resistance. Resin penetrates the quartzite’s pores and micro-cracks to create a bond strengthening the stone’s structure and producing a smooth, protective surface. Along with making a stronger stone, this infusion process stops dust, water, and other particles from seeping into the quartzite, so lowering wear over time.

The epoxy’s strength and the natural durability of quartzite make for a powerful combination. Although quartzite is already among the toughest natural stones, by coating it with epoxy the stone gets more resistance against general surface wear, scrapes, and scratches. For surfaces like kitchen counters, flooring in busy areas, or commercial uses—wherever there is significant use—epoxy-filled quartzite is a great choice.

The Science Behind the Abrasion Resistance of Epoxy-Quartzite Composites

When we consider abrasion resistance, we should take into account the interactions among several materials under friction. Highly durable and dense, quartzite is naturally resistant to many kinds of physical abuse. Epoxy resin fills in micro-cracks and pores, so producing an even harder and more cohesive surface. This infusion serves as a buffer spreading stress over the surface, so lowering the possibility of chipping or scratching.

Epoxy’s chemical structure also plays a role. Its remarkable hardness and resilience from great cross-link density help to explain abrasion resistance. Epoxy resin creates a strong, permanent bond with quartzite, so transforming the surface of the stone into a quite durable composite material unlike other fillers that might weaken over time or detach under strong impact. The end effect is a surface that keeps its original look for longer periods of time and can resist daily use without showing symptoms of wear.

Key Benefits of Epoxy-Filled Quartzite in High-Wear Environments

Enhanced Scratch and Abrasion Resistance: Epoxy-filled quartzite provides an added layer of protection against scratches and abrasions, making it suitable for high-traffic areas. For counters, flooring, and work surfaces where sharp or hard objects come into regular touch, this is perfect.

Reduced Surface Deterioration: Unlike untreated quartzite, which may gradually wear down or lose its luster over time, epoxy-filled quartzite remains smooth and resistant to surface degradation. The epoxy closes the natural pores of the stone, so preventing friction-related damage.

Longer Lifespan: By protecting the surface from everyday wear and tear, epoxy extends the overall life of quartzite, making it a more cost-effective option in the long run. For commercial environments where maintenance budgets are a factor, epoxy-filled quartzite is therefore a great choice.

Preservation of Aesthetic Quality: Epoxy does not only protect but also enhances the quartzite’s appearance. It accentuates the inherent colours and patterns of the stone while maintaining its gloss and texture. Acting as a “shield of beauty,” the resin layer makes sure the stone stays aesthetically pleasing for years.

Enhanced Cleanability: Quartzite filled with epoxy is more maintainable than untreated stone. The resin layer makes it simple to clean spills and stains since it stops dirt and trash from embedding into the stone. For flooring in kitchens and bathrooms as well as counters, this is a useful benefit.

Challenges of Using Epoxy-Filled Quartzite

Despite the numerous advantages, there are some considerations to keep in mind when using epoxy-filled quartzite. UV light can be sensitive to epoxy resin, thus if the quartzite is left in direct sunlight for extended periods of time, yellowing or discolouration may result. Using UV-resistant epoxy formulations or arranging epoxy-filled quartzite surfaces in areas with little sunlight exposure will help to lessen this. Another consideration is that the epoxy application process calls for accuracy; improper application can cause uneven surfaces or bubbles, so influencing appearance as well as durability. Still, these problems are controllable, and for those looking for long-lasting durability, epoxy-filled quartzite is a reasonable choice overall.

Future of Epoxy-Quartzite Composites in Surface Applications

The possibilities for epoxy-filled quartzite in many uses keep growing as epoxy resin formulations advance. More UV-resistant, environmentally friendly, and customisable epoxies that can satisfy even more exact design and durability requirements could be among future advancements. From home kitchens to busy commercial areas, this composite material should show up in more high-demand surroundings as epoxy technology gets more advanced.

A revolutionary material, epoxy-filled quartzite adds a strong, protective layer to improve the natural durability and beauty of quartzite. This creative mix accentuates the best qualities in both materials and offers an abrasion-resistant surface capable of handling heavy use without compromising appearance. Although there are some difficulties, the advantages of epoxy-filled quartzite much exceed these factors, thus it is a great option for everyone looking for a strong, low-maintenance, appealing surface. We can expect even more uses of epoxy-filled quartzite in demanding environments, providing a strong solution for the long-term beauty and strength of natural stone surfaces, as epoxy and composite technologies develop.

Post time: 11 月-11-2024