quartzite has become a popular choice in the building and interior design industries due to its durability, non-porous surface, and unique aesthetic appeal. Like all materials, though, quartzite is not impervious to the elements or wear over time. Now let me introduce epoxy resin, a substance transforming our methods of enhancing and changing stone surfaces. Epoxy resin applied to quartzite surfaces produces a strong protective layer that not only increases durability but also accentuates the natural beauty of the stone, so improving its appeal and practical value for many uses. We shall explore in this post the applications of epoxy resin in quartzite surface modification, its advantages, and what makes it an interesting alternative in the field of stone care and modification.

Epoxy Resin

What Is Epoxy Resin and Why Is It Used on quartzite?

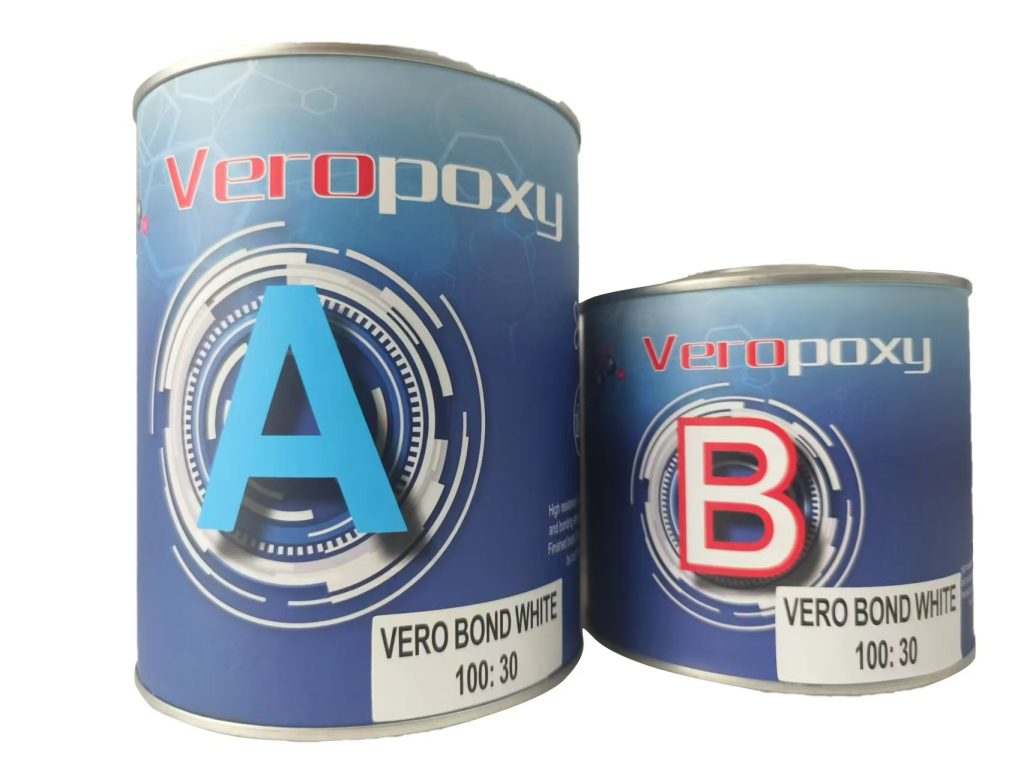

Versatile synthetic polymer with adhesive strength, hardness, and chemical resistance is epoxy resin. Epoxy resin serves as a protective layer when applied on quartzite surfaces, creating a barrier that guards the stone from stains, abrasions, and other surface damage. Epoxy offers a more strong, glossy finish than traditional sealants that can accentuate the colour and texture depth of the stone. Because it can prolong the life of quartzite surfaces—especially in high-traffic areas like kitchens, bathrooms, and businesses—this technique of stone modification has grown ever more popular.

The Application Process: How Does Epoxy Resin Transform quartzite?

Applying epoxy resin to quartzite is a remarkable mix of science and artistry. First, to guarantee best adhesion, the quartzite surface is painstakingly cleaned and ready. Whether it’s a high-gloss shine, a matte finish, or even a minor tint to change the natural colour of the stone, the epoxy resin is then combined with any desired pigments or additions to create the intended visual effect. The resin is then gently sprayed on the surface to create an equal layer. Applied once, the resin cures and hardens into a glossy finish that shields the stone underfoot.

The Benefits of Epoxy Resin on quartzite Surfaces

Using epoxy resin on quartzite surfaces brings several significant benefits that extend beyond mere aesthetics:

Enhanced Durability: Epoxy resin creates a tough, resilient coating that can withstand wear and tear from everyday use. Particularly helpful in busy or commercial environments, it shields the quartzite from scratches, abrasions, and minor impacts.

Though non-porous, quartzite surfaces can nonetheless get stains from extended contact to chemicals like coffee, wine, or oils. Epoxy provides an additional layer of protection, which increases the difficulty for these liquids to pass the surface.

Easy Maintenance: Maintaining the surface gets rather simple with epoxy. With just a damp cloth, the smooth, non-porous coating makes wiping clean simple and resists grime accumulation.

The glossy finish of epoxy resin can accentuate the inherent beauty of the quartzite, so augmenting the colour and pattern depth of the stone. For a unique look, the resin can even be mixed with colours or tinged.

Epoxy resin is resistant to many common household chemicals, so lowering the risk of damage from unintentional cleaning agent or acid chemical spills.

Potential Challenges of Using Epoxy Resin on quartzite

While epoxy resin offers numerous benefits, there are a few potential drawbacks to consider. Epoxy may yellow or degrade over time depending on UV exposure; this could be due to direct sunlight. Furthermore, the application process calls for accuracy and knowledge; improper application might cause uneven coverage, bubbles, or streaks, so compromising the look of the stone. Epoxy removal can be labour-intensive in cases when reapplication is required. Still, these difficulties are usually negligible when compared to the whole advantages of epoxy on quartzite surfaces.

Future Potential: Epoxy Resin Advancements in Stone Surface Modification

Epoxy resin is increasingly being used in stone modification; new formulations provide more environmentally friendly choices, faster curing times, and improved UV stability. Furthermore, advances in colour palletising and texture enhancement make epoxy a very flexible material that builders and designers are embracing for artistic endeavours. The possibility of more development in epoxy technology suggests a time when stone surfaces could become even more strong, flexible, and aesthetically pleasing, so enhancing the function of epoxy in quartzite modification.

Epoxy Resin

Offering a useful but aesthetically pleasing solution to increase the lifetime of the stone and preserve its perfect appearance, epoxy resin has revolutionised quartzite surface modification. Designers and homeowners both will be able to enjoy a more durable, stain-resistant, and beautiful surface that resists daily use by layering epoxy on quartzite surfaces. Although epoxy on quartzite presents difficulties, its advantages much exceed its disadvantages, thus it is a recommended method for improving and safeguarding quartzite stone surfaces. We should expect even more creative uses that will push quartzite modification to new limits as epoxy technology develops.

Post time: 11 月-11-2024