Epoxy resin adhesives have transformed the way we work with stone, enabling stronger and more reliable bonds than ever before. Epoxy resin has evolved into a necessary element in stone processing whether it’s architectural stone features, marble counters, or detailed sculptures. But reaching an ideal bond that withstands environmental stress and time is not as easy as spreading glue and calling it good for today.

The stone industry, with its wide array of materials and applications, requires careful attention to the nuances of epoxy resin application. The ultimate bond can be affected by surface preparation, adhesive formulation, curing methods, and environmental conditions among other things. Working with stone and epoxy resin, this article explores the techniques and advice that can enable the best possible adhesion. Examining every stage of the bonding process will help us to maximise strength, durability, and visual quality in stone projects.

Key Strategies for Optimizing Epoxy Resin Adhesion in Stone Processing

Surface Preparation: The Foundation of Strong Adhesion

The surface condition of the stone determines the strength of an epoxy resin bond in a most important way. The adhesive will not stick correctly if the surface is overly smooth or covered in dust, oil, or moisture. By creating micro-porosities in the stone surface, roughening helps the epoxy resin to penetrate and lock in, so strengthening the bond. Roughen the surface with a sandblaster or abrasive pad, then clean with a solvent to guarantee a clean, textured surface on which to adhere the epoxy resin.

Choosing the Right Epoxy Resin Formulation

Not all epoxy resin adhesives are created equal. There are formulations designed especially for different kinds of stone and environmental settings. Some epoxy resins, for instance, are more flexible, which aids in the natural movement of stone under temperature swings. Others are meant to withstand UV light, which is absolutely vital for outdoor uses. Achieving long-lasting adhesion in the project depends on knowing its needs and selecting the correct kind of epoxy resin.

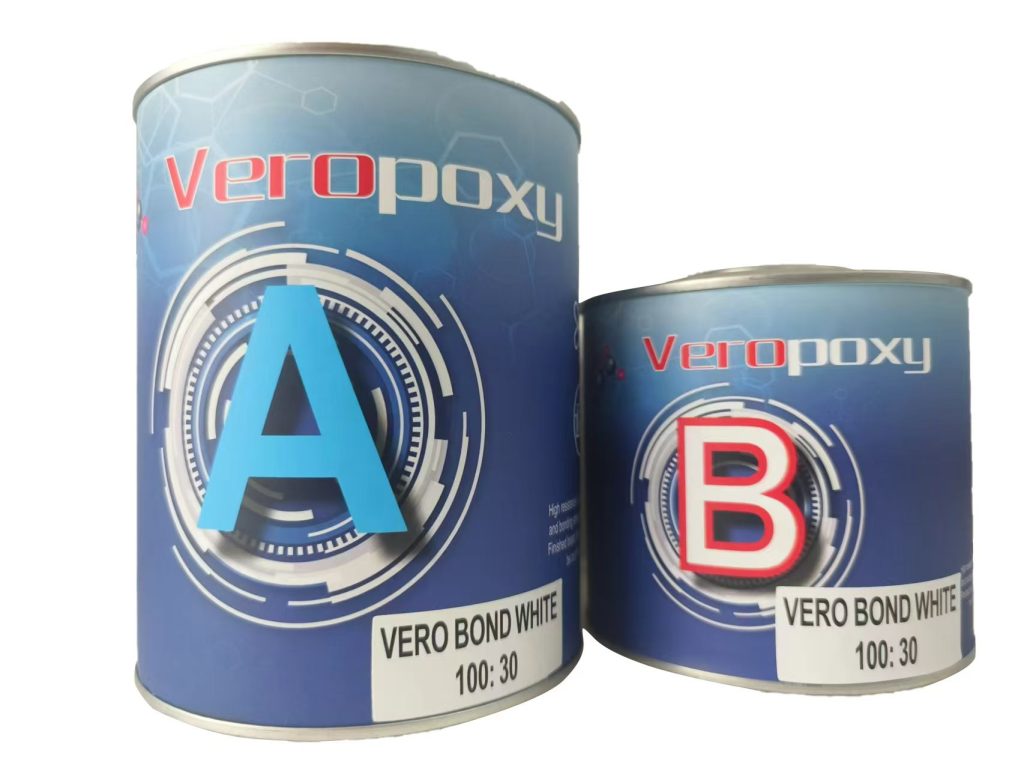

Optimizing Epoxy Resin Mixing Ratios

Epoxy resin adhesives often come with precise mixing instructions that must be followed to achieve the intended bond strength. Inaccurate ratios might produce a weaker bond or perhaps stop the epoxy resin from curing as it should. Following manufacturer recommendations and measuring and mixing the epoxy resin components using exact tools guarantees the epoxy resin reaches its full bonding capacity. To further prevent contamination, many experts also advise using a specific mixing container and stirring utensil.

Applying Adhesive Evenly and Consistently

Uneven application might cause weak areas in the bond and air pockets, so compromising its durability. Even adhesion is achieved by spreading the epoxy resin adhesive in a homogeneous layer over the stone’s whole surface. One can guarantee constant thickness using a notched trowel or applicator. For bigger stone surfaces, think about sectioning epoxy resin to prevent early curing.

Controlling Curing Conditions

Curing is a critical stage in the epoxy resin bonding process, as it determines the bond’s ultimate strength. The quality of the bond and the curing time can be much changed by temperature and humidity. While cold conditions can slow down or completely stop curing, warmer temperatures usually speed up it. Until the epoxy resin completely cures, the bonded stone should ideally be kept under controlled conditions with constant temperature and humidity. Epoxy resin should not be applied for outdoor projects on very hot, cold, or humid days.

Using Additives for Enhanced Performance

Some epoxy resin formulations allow for additives to improve specific characteristics, such as flexibility, impact resistance, or chemical durability. Adding rubber particles, for example, can improve the shock absorption capacity of epoxy resin, so increasing its suitability for mechanical stressed areas. When working with stones in outdoor projects or high-traffic areas, these additions can especially help.

Minimizing Shrinkage and Creep

As epoxy resin adhesives cure, shrinkage can cause internal stress in the bond. For large or heavy stone pieces especially, this is quite troublesome. Applying a secondary bonding layer or low-shrinkage epoxy resin formulations will help to solve this problem. Important for long-term durability, some epoxy resins also resist “creep,” the slow deformation of the adhesive over time.

Pre-Curing and Heat Treatments

In some situations, heat can speed up the curing process and strengthen bonds. Pre-curing methods including gently heating the epoxy resin following application can boost adhesion and help prevent cold spots that might compromise the bond. Heat treatment should be used carefully, though, to avoid overheating, which can discolour the stone or damage it.

Environmental Considerations for Sustainable Bonding

Epoxy resin use comes with environmental considerations, as it often includes chemicals that can impact air quality and worker health. Simple ways to make a safer workspace are choosing low-VOC (volatile organic compounds) formulations and applying appropriate ventilation in the workstation. Moreover, precisely measuring epoxy resin helps to minimise waste, so lowering the environmental impact of stone processing operations.

Testing the Strength and Durability of the Bond

Testing the epoxy resin-stone bond before the final installation can prevent costly rework. On small, bonded samples, some experts evaluate the performance of the adhesive under load using shear or tensile tests. This initial test guarantees the bond satisfies the criteria of the project and offers important information on its durability.

Optimizing epoxy resin adhesive application in stone processing requires more than just selecting the right product. To get a bond that lasts, it’s a complete approach including surface preparation, appropriate mixing, controlled curing, and testing. Following these techniques will help Stone Industry professionals create stronger, more dependable bonds that not only satisfy structural needs but also resist environmental challenges. Epoxy resin adhesives can really maximise stone in modern building and design by means of meticulous attention to every phase of the process.

Post time: 11 月-07-2024