Low-Expansion Epoxy for Semi-Precious Stone Seam Filling – 5090 / D30M-BS

Overview

Product Description

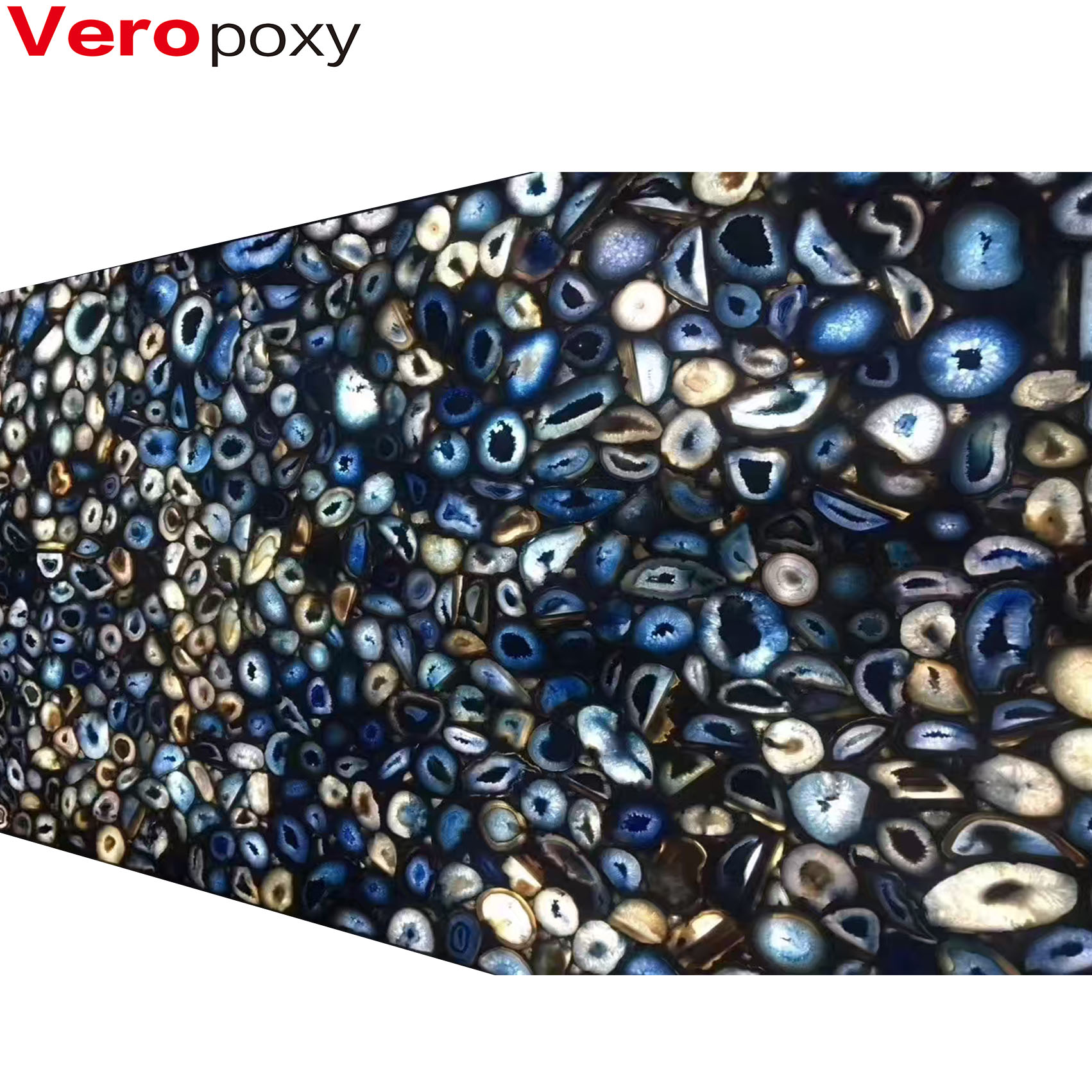

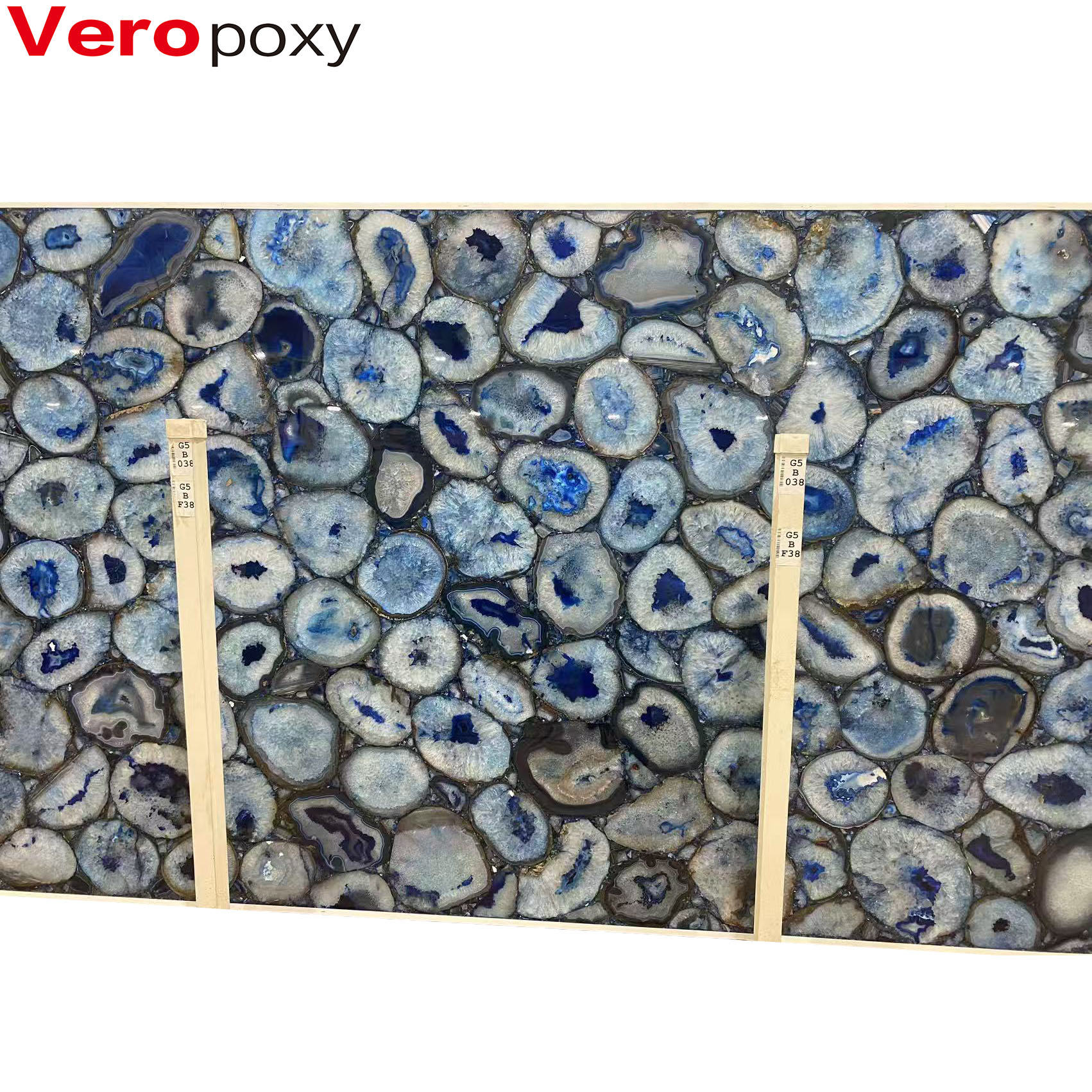

Low-Expansion Epoxy for Semi-Precious Stone Seam Filling – 5090 / D30M-BS is specially engineered for agate, onyx, and composite semi-precious stone slabs. Its low expansion and low internal stress formulation prevents panel warping while delivering seamless joint filling with no tactile feel after curing.

Product Description

5090 / D30M-BS is a professional epoxy system developed for seam filling and bonding of semi-precious stone slabs. The formulation focuses on dimensional stability, extremely low expansion, and uniform curing behavior to avoid slab deformation. Once cured, the filled seams remain smooth and undetectable by touch, meeting the high aesthetic standards required for luxury stone applications.

Product Features & Specifications

| Feature | Low expansion, seamless joint filling, no panel warping |

|---|---|

| Applicable Material | Semi-precious stone slabs (agate, onyx, composite stone) |

| Epoxy System Code | 5090 / D30M-BS |

| Epoxy System Ratio | 100:30 |

| Durability | High stability and long-lasting after curing |

| Ease of Use | Easy to mix and apply, no special tools required |

| Curing Time | 80 minutes |

| Yellowing Resistance | Very low yellowing |

| Recommended Temperature | 24°C |

| Viscosity | 400–600 CPS |

Problems It Solves

- Prevents slab warping caused by internal stress

- Eliminates tactile feel on filled seams after curing

- Reduces deformation risks in composite semi-precious slabs

Recommended Applications

- Seam filling of agate and onyx slabs

- Bonding and repair of semi-precious composite stone panels

- Luxury stone countertops and decorative panels

Key Performance Advantages

- Low expansion ensures dimensional stability

- Low internal stress prevents bending and warping

- Seamless surface finish with no tactile sensation

Product System Description

5090 resin combined with D30M-BS hardener forms a balanced epoxy system with controlled reactivity and uniform curing behavior. The system is optimized for semi-precious stone applications where appearance and structural integrity are equally critical.

Processing Suggestions

- Ensure stone surfaces are clean and dry before application

- Mix resin and hardener accurately according to the specified ratio

- Apply evenly along seams and allow full curing before polishing

Suitable Stone Types

- Agate stone slabs

- Onyx slabs

- Semi-precious composite stone panels

Packaging & Supply

Available in industrial packaging options. Direct supply from China epoxy resin manufacturer and factory, supporting stable bulk orders for stone processing plants.

FAQ

- Is this epoxy suitable for semi-precious stone slabs?

Yes, it is specifically formulated for agate, onyx, and composite semi-precious stones. - Does the epoxy cause slab warping after curing?

No, the low-expansion and low internal stress formulation minimizes deformation risks. - Will the seam be noticeable after polishing?

The cured seam remains smooth with no tactile feel, ensuring a seamless finish. - What is the recommended working temperature?

The optimal application temperature is around 24°C.

For semi-precious stone applications where appearance, dimensional stability, and seamless finishing are critical, 5090 / D30M-BS offers a reliable low-expansion epoxy solution that balances performance with long-term stability.