Commercial Industrial High Gloss Semi-precious Stone Look Epoxy Resin Flooring for Residential

- Feature: Epoxy Resin for Semi-Precious Stone

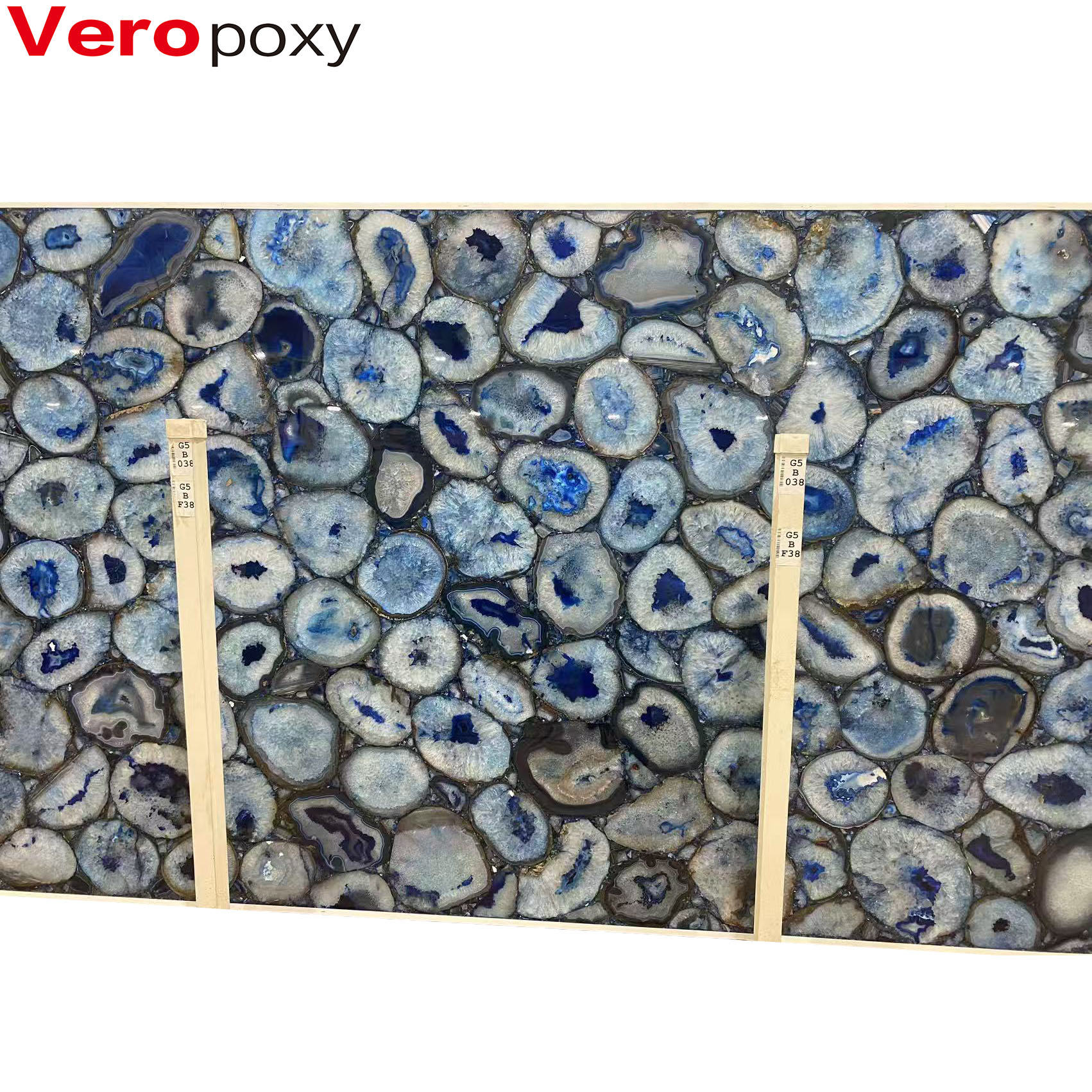

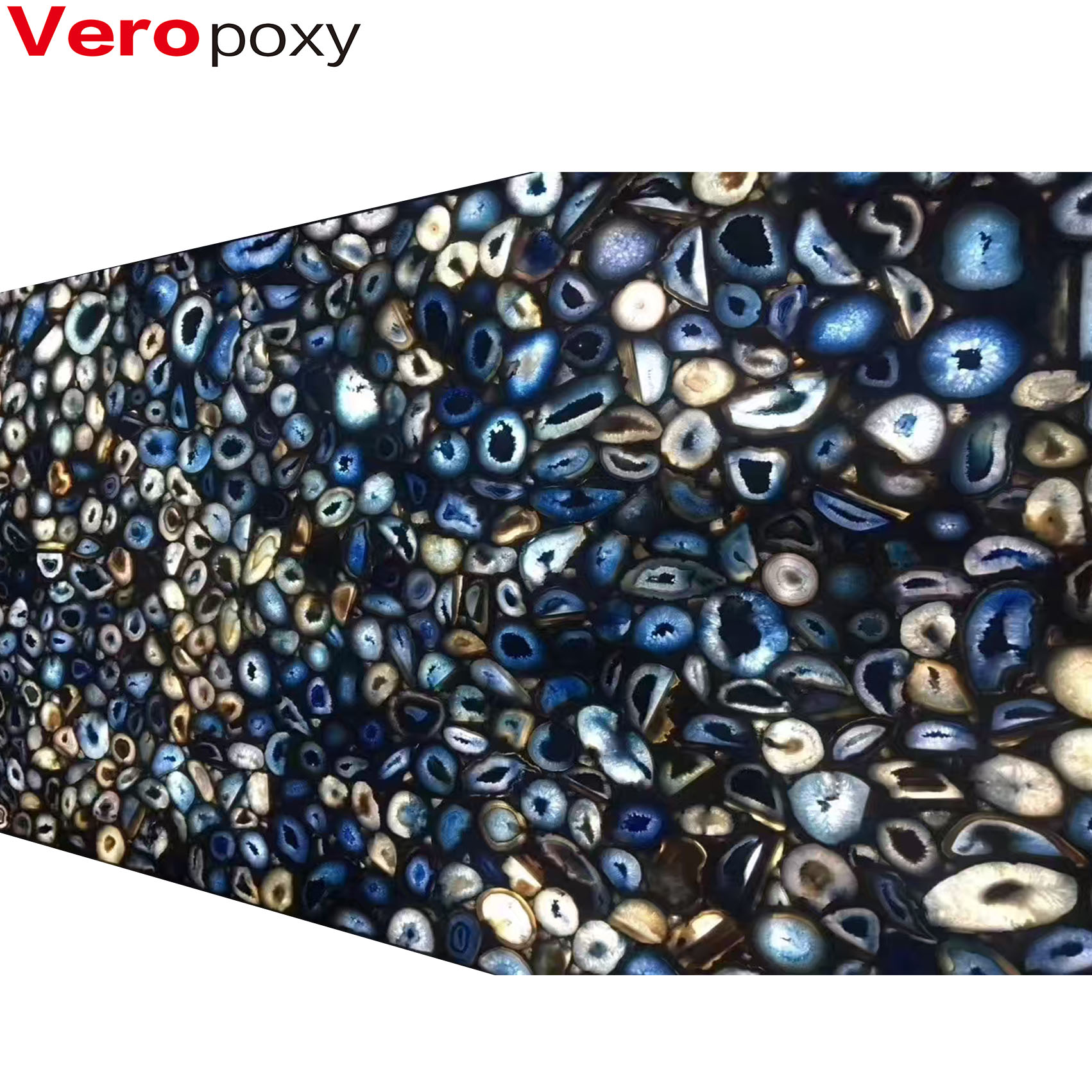

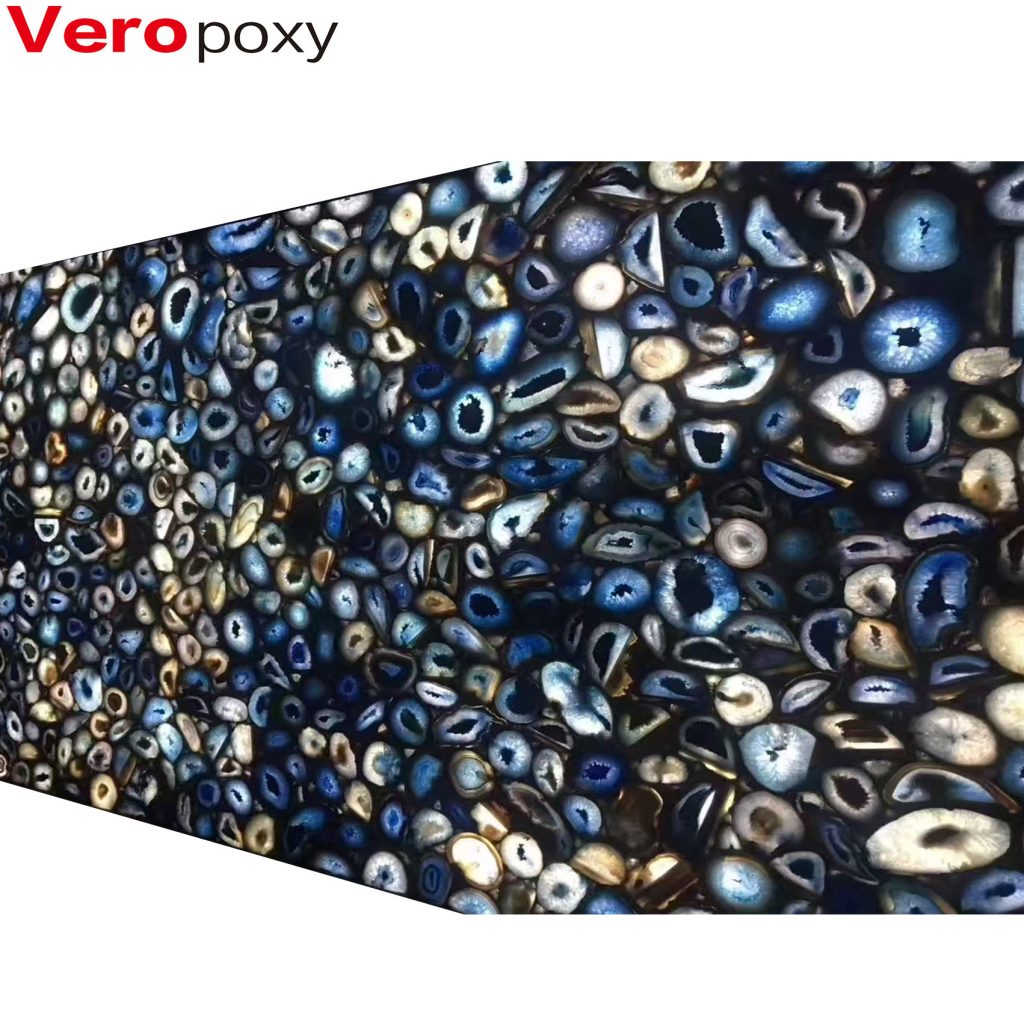

- Applicable material: Agate , White Crystal , Pink Crystal , tiger`s eyes

- Epoxy system code: 5080+D30M-BS

- Epoxy system ratio by weight: 100:30

- Curing effect: Forms a liquid sealing layer

- Durability: High stability and long-lasting after curing,good yellowing resistance , low viscosity , strong Bonding Low watermark effection .

- Ease of Use: Easy to mix and apply, no special tools required

Overview

Veropoxy is a high performance epoxy compound designed for semi-precious stone panels, primarily for surface treatment, enhancement and repair. Composed of a resin and a hardener, it forms a strong protective coating. Suitable for use on agate, jasper and tiger’s eye, it enhances their durability and appeal in high-end architectural decoration and interior design.

Product Description

Product Information

Particularly designed for semi-precious stone panels, Veropoxy is a high-performance epoxy resin compound. Mostly it is used for surface treatment, augmentation, and repair of semi-precious stone panels. Comprising component A (resin) and component B (curing agent), the product creates a strong and clear protective coating on the surface of the stone via chemical reaction. Mostly employed in high-end architectural decoration and interior design, veropoxy is appropriate for many semi-precious stone panels like agate, jasper, tiger eye stone, etc., making them more durable and attractive.

Product Features

| Feature | Epoxy Resin for Semi-Precious Stone |

| Applicable material | Agate , White Crystal , Pink Crystal , tiger`s eyes |

| Epoxy system code | 5080+D30M-BS |

| Epoxy system ratio by weight | 100:30 |

| Curing effect | Forms a liquid sealing layer |

| Durability | High stability and long-lasting after curing,good yellowing resistance , low viscosity , strong Bonding

Low watermark effection . |

| Ease of Use | Easy to mix and apply, no special tools required |

Affects of Epoxy Resin on Semi-precious Stones

Processing and treating semi-precious stones depends on epoxy resin in significant part. It may accentuate the beauty and durability of semi-precious stones. Several main impacts of epoxy resin on semi-precious stones are listed here:

1. increase surface gloss

Surface coating of semi-precious stones may help to improve their shine and clarity by means of epoxy resin. Applying a little coating of epoxy resin makes the semi-precious stone seem more full and brilliant, therefore improving its visual impact. Some semi-precious stones with inherent fractures or additional surface flaws find this approach very popular. Its market worth and attractiveness are raised by coating alteration.

2. Filling cracks and defects

Little cracks or holes abound in many natural semi-precious stones. These flaws will compromise the stone’s general structural strength and beauty. Excellent filling and adherence of epoxy resin allow one to fix fractures and flaws, thereby restoring the semi-precious stone to seem more whole and substantial. After curing, epoxy glue makes a firm connection that strengthens the stone’s endurance and stability by penetrating into the minute fissures.

3. Improved robustness

Epoxy resin treatment of semi-precious stones increases their durability noticeably. Epoxy resin’s hardness increases semi-precious stone resistance to chemical corrosion, wear, and impact. Semi-precious jewelry or decorations so lengthen their service life by being less prone to harm during regular wear or usage.

4. Enhanced speed of processing

Some semi-precious stones are readily damaged during cutting and polishing and have either poor hardness or great brittleness. Treating semi-precious stones with epoxy resin before processing helps to strengthen their durability and hence minimize the phenomena of fragmentation during processing. This not only increases processing efficiency but also lets the final product preserve more integrity and attractiveness.

5. Modifying visual impacts

Moreover, the visual impacts of semi-precious stones may be altered using epoxy resin. For instance, new color and texture effects may be produced by adding pigments or small particles to epoxy resin and then coating it on the surface of semi-precious stones or injecting it into fissures, therefore improving the decorative value of the stones. Some semi-precious stones with ordinary look would be especially suited for this technique as they have greater artistic worth.

6. Minize fading and oxidation.

By means of oxygen and moisture in the air, the epoxy resin protection layer may efficiently minimize the erosion of semi-precious stones, thereby avoiding oxidation and fading. Certain natural gemstones, particularly those with stronger hues, are prone to color alteration from air or UV radiation. Their color may be preserved from changing and kept looking long-term lovely by epoxy resin coating.

Common problems of epoxy resin for semi-precious stone plates

Issues with bubbles during treatment: Particularly during the coating process, bubble difficulties might arise when treating semi-precious stone plates with epoxy resin. Should these bubbles not be controlled in time, they might compromise surface gloss and clarity. Correct actions must be done throughout the building phase to prevent bubble development.

Though epoxy resin possesses anti-yellowing qualities, under long-term UV exposure it may still exhibit some yellowing. This is something that should be taken into account for semi-precious stone plates that have to keep their natural hue over a lengthy period.

Epoxy resin must be built in a somewhat dry and temperature-appropriate surroundings. Either too high or too low temperatures might influence resin’s curing ability as well as final appearance. Environmental control should get some thought while building.

Quality control of first coating: It is important to guarantee the homogeneity and sufficiency of the resin to prevent unequal coating thickness or local cracking, which may influence the general aesthetics and protective effect of the semi-precious stone plate. Applying the first layer helps to guarantee this homogeneity and sufficiency of the resin.

Though epoxy resin itself has great resistance to acid, alkali and chemical corrosion, long-term resistance testing is still necessary for certain particular chemicals to ascertain their long-term usage impact in various surroundings.

These issues influence the application impact and service life of epoxy resin on semi-precious stone plates; so, they should be given attention and resolved throughout usage and construction.

Precautions:

Use this product in a well-ventilated area.

Keep out of reach of children and pets.

Read the product manual carefully before use.

Packaging Specifications:

25 kg container

200 kg container

1000 kg container

Shelf Life:12 months when unopened.

Storage Conditions:

Store in a cool, dry, and well-ventilated area, away from fire and high temperatures.

With this introduction, you can fully understand the product features and usage methods of the Epoxy Resin Sealant for Semi-Precious Stones. We are committed to providing high-quality products to meet your needs for the maintenance and repair of semi-precious stones.