Hot selling flexible epoxy sealant ab glue composite sealant fast curing ab epoxy resin granite adhesive

- Feature: Epoxy Resin for Granite

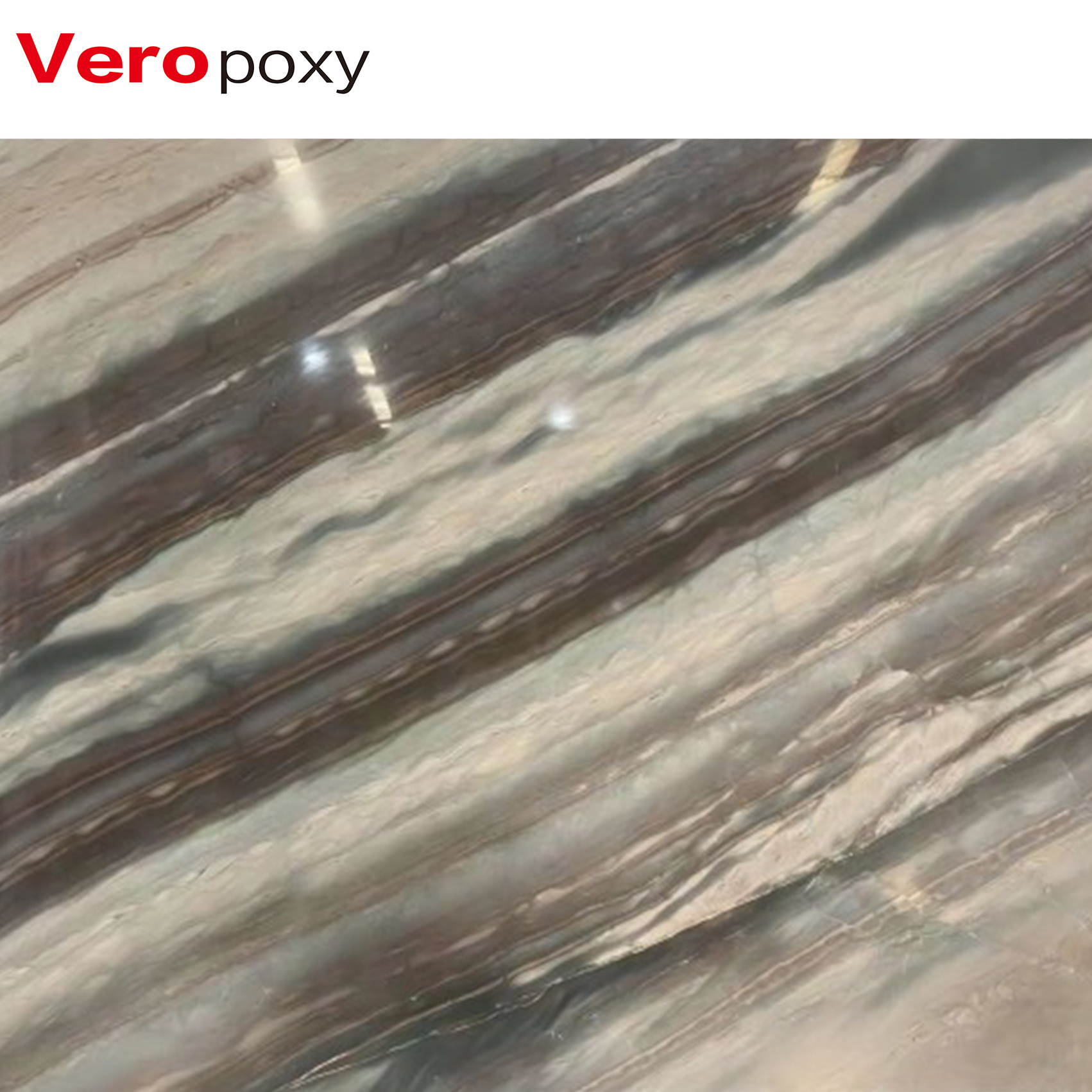

- Applicable material: Okapi white , Pandora , Amazonite Blue

- Epoxy system code: 5099+B25Q-KG

- Epoxy system ratio by weight: 100:25

- Curing effect: Forms a liquid sealing layer

Overview

Veropoxy epoxy adhesive is a fast curing, two-component epoxy resin adhesive with excellent aging, moisture, electrical insulation, elastic impact resistance, and high breakdown voltage. It is suitable for bonding and sealing granite, stone, and buildings, and is widely used in decoration for homes, hotels, and public halls. It can be bonded to walls, furniture, or other materials, making it ideal for stone slab bonding. It is not easy to break.

Product Description

Veropoxy epoxy adhesive is a two-component, room temperature curing, fast curing epoxy resin adhesive. It has the characteristics of fast curing, and has better flexibility than ordinary epoxy adhesives and is not easy to break.

It has excellent aging resistance, moisture resistance, electrical insulation, elastic impact resistance and high breakdown voltage. It is suitable for various bonding and sealing of granite, stone, and buildings.

As a new material in the decoration market, it is widely used in the decoration of homes, hotels and public halls.

It can be bonded to the wall as a living room background wall, or made into a washing table, sink, kitchen platform, stairs, or bonded to other materials as furniture.

Our Veropoxy two-component fast curing epoxy adhesive is very suitable for stone slab bonding.

Product Features:

|

Feature |

Epoxy Resin for Granite |

| Applicable material | Okapi white , Pandora , Amazonite Blue , |

| Epoxy system code | 5099+B25Q-KG |

| Epoxy system ratio by weight | 100:25 |

| Curing effect | Forms a liquid sealing layer |

|

Durability |

High stability and long-lasting after curing,good yellowing resistance , low viscosity , strong Bonding Low watermark effection . |

| Ease of Use | Easy to mix and apply, no special tools required |

Product Highlights

* Simple User Interface

Perfect texture, convenient 1:1 ratio, easy to use for both beginners and experts. No need to wear a mask while working.

* Safety First

Made of premium non-toxic ingredients, 100% safe for indoor and outdoor use, epoxy resin does not contain any harmful chemicals, reactions or fumes!

* Strong UV resistance

Self-leveling formula provides top-notch UV protection coating Experience powerful light and excellent gloss, guaranteed for lifetime use!

Advantages of Epoxy resin for Granite

Epoxy resin is able to provide extremely high adhesion, making granite repairs more solid and less prone to cracking and peeling. Secondly, the high transparency of epoxy resin allows it to blend naturally with granite after curing, and will not cover up the original color and texture of the stone, thereby maintaining the natural beauty of granite. In addition, epoxy resin has excellent water resistance and chemical resistance, effectively protecting granite from water stains, oil stains, acids and alkalis. This durability and stability make epoxy resin an ideal choice for granite repair and protection, which not only improves the life of the stone, but also reduces the cost of subsequent maintenance.

How to use

Surface preparation: Clean the granite surface to ensure that it is dust-free, oil-free and moisture-free.

Mixing: Mix “A” and “B” components according to the proportions in the instructions and stir evenly.

Application: Use a scraper or brush to apply epoxy resin evenly on the granite surface.

Curing: Allow the epoxy resin to cure in a suitable environment, and the time depends on the product instructions.

Post-processing: After curing, grind and polish as needed to achieve the best results.

Precautions

When using epoxy resin, wear appropriate protective equipment such as gloves, goggles and masks.

Ensure that the work area is well ventilated to avoid inhaling harmful gases.

Store unused epoxy resin properly according to the product instructions and avoid direct sunlight and high temperatures.

Storage of epoxy resin

Epoxy resin should be stored in a dry, cool, well-ventilated room, avoiding direct sunlight and high temperature environment. Usually between 15℃ and 25℃, the appropriate storage temperature controls the relative humidity between 40% and 60%.

Epoxy resin should be stored in corrosion-resistant, well-sealed containers to avoid contact with moisture, air and other materials. The storage space should have clearly visible safety signs containing flammable, toxic and corrosive warnings.

Epoxy resin is a flammable substance, so fire prevention should be considered when storing it. Store epoxy glue away from flammable objects or fire sources to prevent fire.

Avoid sunlight, as long-term exposure of epoxy resin will affect its performance and quality. Therefore, epoxy resin should be kept dark and away from direct sunlight.

Epoxy resin usually has a fixed shelf life, and its performance may change once the shelf life expires. Therefore, before use, you should investigate the shelf life of epoxy resin and try to use it within this range.

Epoxy resins are usually packaged in sealed containers, which are then sealed; therefore, unused resin should be stored in sealed containers. After opening the package, make sure the container is well sealed so that the resin does not absorb moisture or cure due to contact with air.