Granite Crack Repair Epoxy 5099+B25Q-KG

Overview

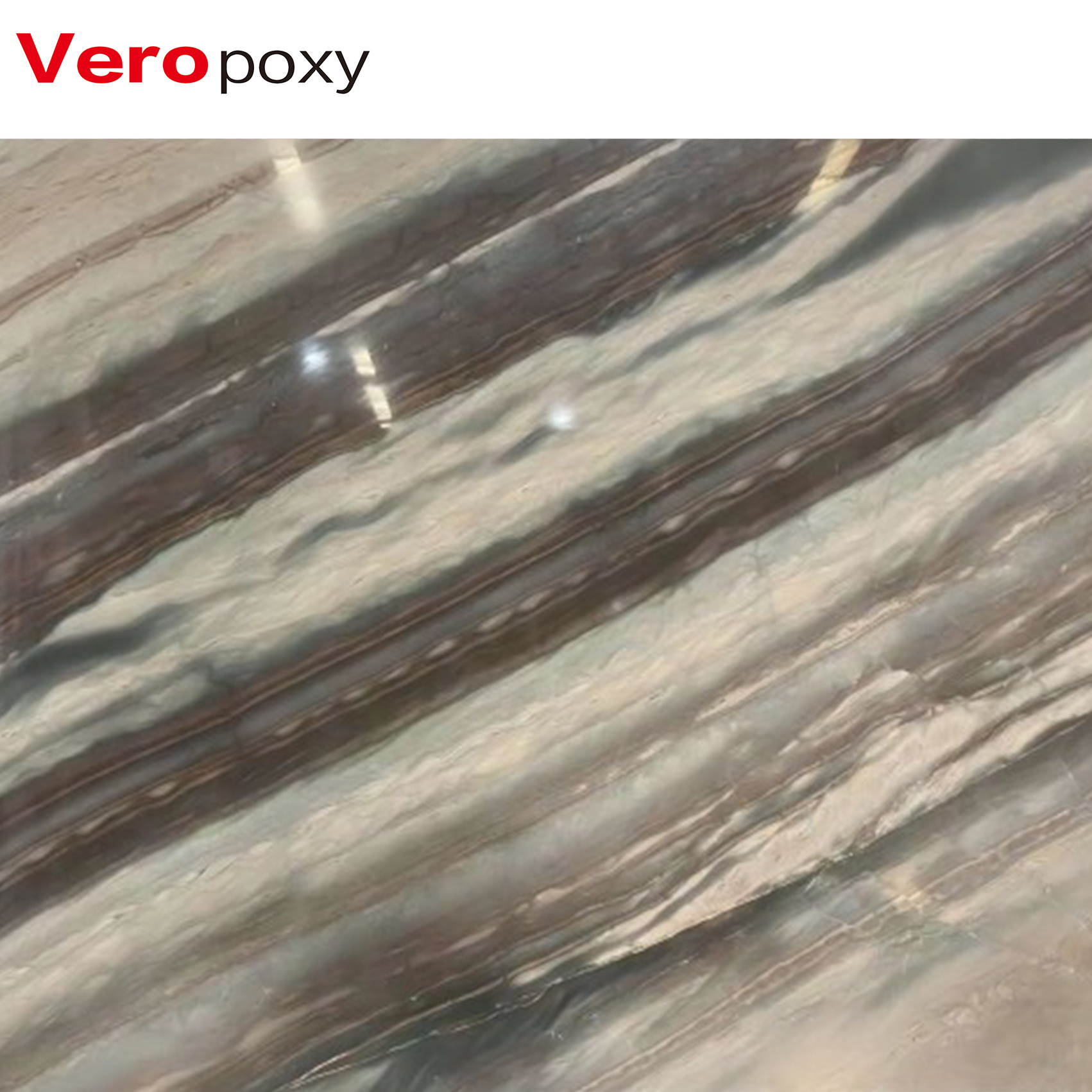

5099+B25Q-KG is an ultra-low viscosity, high-penetration epoxy resin system designed specifically for the stone processing industry. Developed by our leading factory in China, this two-component liquid epoxy acts as a molecular-level reinforcement for granite slabs, filling hairline cracks and invisible micro-fissures to restore structural integrity and enhance the stone’s aesthetic value.

Product Description

Professional Technical Specifications of 5099+B25Q-KG

As a premier China supplier, we ensure that every batch of 5099+B25Q-KG meets international industrial standards. The following table outlines the critical chemical and physical properties of this specialized granite epoxy system:

| Property | Part A (5099) | Part B (B25Q-KG) |

|---|---|---|

| Appearance | Clear Liquid | Pale Yellow / Clear |

| Viscosity (25°C) | 50-100 mPa.s | 20-40 mPa.s |

| Mixing Ratio (Weight) | 3 | 1 |

| Pot Life (100g at 25°C) | 45 – 60 Minutes | |

| Full Cure Time | 24 Hours | |

| Hardness (Shore D) | ≥ 82 | |

Why 5099+B25Q-KG is Essential for Granite Processing Factories

Modern stone processing requires materials that can withstand the rigors of automated cutting and polishing lines. Many exotic granite slabs contain natural fissures that can lead to breakage during production. Our 5099+B25Q-KG formula offers an industrial solution to these challenges.

1. Deep Capillary Penetration

Traditional adhesives sit on the surface, but 5099+B25Q-KG is engineered with a molecular weight that allows it to travel deep into the granite’s structure. This “wicking” action ensures that even the thinnest cracks are bonded from the inside out, significantly reducing the slab’s fragility.

2. Enhanced Optical Clarity

Color matching is a common headache for stone fabricators. This resin system features a refractive index closely aligned with natural quartz and feldspar found in granite. Once cured, the epoxy becomes virtually invisible, maintaining the stone’s original color and depth without the “dark line” effect typical of inferior resins.

3. Superior Chemical Stability

As a leading manufacturer, we understand that granite is often used in demanding environments. Our epoxy is resistant to household chemicals, oils, and mild acids, making it perfect for both kitchen countertops and high-traffic commercial flooring.

Application Guidelines: Maximizing Success with 5099+B25Q-KG

To ensure 100% effectiveness, follow these professional steps used by top-tier China stone suppliers:

- Preparation: The stone must be completely dry. We recommend pre-heating the slab to 40-50°C to open the pores and drive out any latent moisture.

- Mixing: Use a digital scale to measure Part A and Part B according to the 3:1 weight ratio. Stir slowly for 3 minutes to avoid introducing air bubbles.

- Application: Pour the resin onto the fissure or apply it over the entire slab surface using a squeegee. Allow it to sit for 15-20 minutes to permit deep penetration.

- Curing: Maintain a stable temperature during the initial 4-6 hours of curing. Do not move the slab until the resin has reached a tack-free state.

- Polishing: Once fully cured (24 hours), the slab can be polished using standard diamond abrasives. 5099+B25Q-KG will polish to the same high gloss as the granite itself.

The China Manufacturer Advantage: Quality and Value

Choosing a reliable factory for your stone adhesive needs is crucial. By partnering with us, you gain access to a decade of R&D in stone chemistry. Our production facility utilizes advanced filtration systems to ensure the highest purity of raw materials, resulting in a resin that is consistent from batch to batch. We provide comprehensive MSDS and TDS documentation to support global shipping and safety compliance.

5099+B25Q-KG represents the peak of low-viscosity epoxy technology. For factories processing expensive Brazilian or Indian granite, this resin is not just an adhesive—it is an insurance policy. It prevents costly slab fractures during the CNC process and ensures that the final product meets the highest luxury standards. If you are looking for a China supplier that understands the balance between viscosity and bonding strength, this system is the definitive choice.

FAQ Section

-

Q: How does 5099+B25Q-KG differ from standard epoxy adhesives?

-

A: Most adhesives are designed for surface bonding. 5099+B25Q-KG is a “penetrating” resin with a viscosity lower than water, allowing it to infiltrate micro-fissures that standard AB glues cannot enter.

-

-

Q: Is it suitable for white or light-colored granite?

-

A: While 5099+B25Q-KG has excellent clarity, for pure white stones exposed to intense sunlight, we recommend our specialized UV-resistant TL4090BF series. For general indoor granite, 5099 is the industry standard.

-

-

Q: What is the shelf life of this product?

-

A: When stored in original sealed containers in a cool, dry place (below 25°C), the shelf life is 12 months.

-

-

Q: Can I add color pigments to this resin?

-

A: Yes, it is highly compatible with epoxy-based pigment pastes. Only a small amount (0.5% – 2%) is needed to match any granite shade perfectly.

-

-

Q: Do you offer bulk discounts for stone factories?

-

A: As a direct manufacturer, we offer tiered wholesale pricing for 200kg drums or 1000kg IBC tanks. Contact our sales department for a customized quote.

-