Odorless Mesh Backing Epoxy for Summer Production Lines – 4090 / BCO25Q-14

Overview

Product Description

4090 / BCO25Q-14 is an odorless epoxy resin system specially developed for mesh backing processes in summer conditions. It is optimized for drying-line production, offering stable curing, strong mesh adhesion, and a clean, low-impact working environment for stone factories.

Product Description

4090 / BCO25Q-14 is a professional-grade epoxy adhesive designed for stone slab mesh backing processes under high ambient temperatures.

The system is formulated for summer production lines and drying ovens, ensuring controlled curing behavior, excellent fiber wetting, and reliable bonding strength without releasing unpleasant odors during application or curing.

Its odorless formulation makes it particularly suitable for enclosed workshops and continuous production environments, helping improve operator comfort while maintaining industrial-level performance.

Product Features & Specifications

| Feature | Summer-grade odorless mesh backing epoxy |

|---|---|

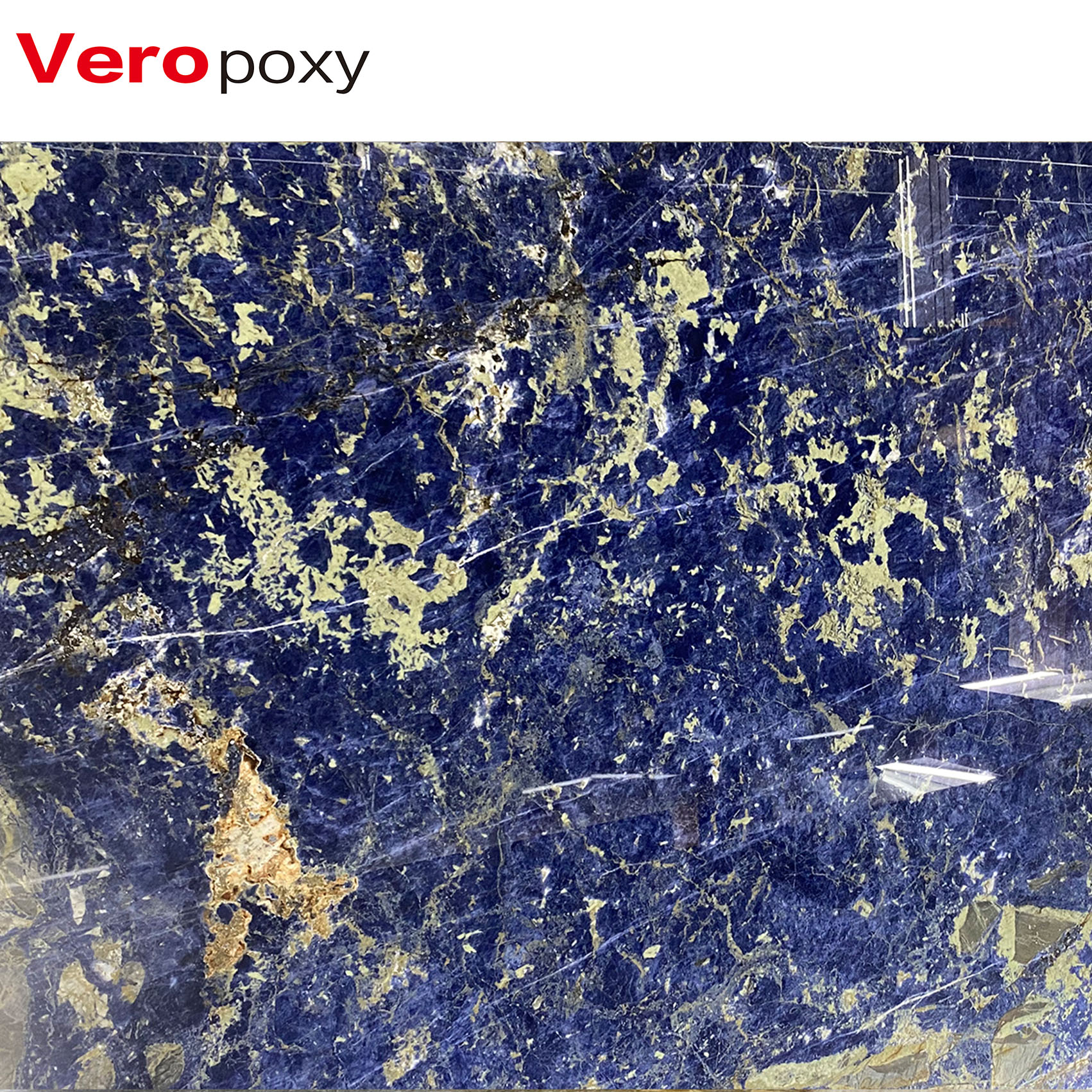

| Applicable Material | Granite, marble, engineered stone slabs |

| Epoxy System Code | 4090 / BCO25Q-14 |

| Epoxy System Ratio | 100 : 25 |

| Durability | High stability and long-lasting after curing |

| Ease of Use | Easy to mix and apply, no special tools required |

| Curing Time | 60 minutes |

| Yellowing Resistance | Standard |

| Recommended Temperature | Summer conditions(28°) / drying-line environments |

| Viscosity | CPS 400–600 |

Problems It Solves

- Unpleasant odor during mesh backing operations

- Unstable curing in high-temperature summer workshops

- Poor mesh adhesion caused by overly fast or uneven curing

- Incompatibility with drying-line production systems

Recommended Applications

- Stone slab mesh backing on automated production lines

- Drying oven and heated curing line processes

- High-temperature summer manufacturing environments

- Factories requiring low-odor or odorless working conditions

Key Performance Advantages

- Odorless formulation improves workshop air quality

- Stable curing behavior under summer temperatures

- Excellent fiber wetting and mesh penetration

- Consistent bonding strength after oven or line curing

Product System Description

4090 / BCO25Q-14 is a two-component epoxy system designed specifically for mesh reinforcement processes.

The resin and hardener combination provides controlled reactivity suitable for elevated temperatures, ensuring reliable curing without brittleness or surface defects.

Processing Suggestions

- Ensure accurate mixing ratio for consistent curing results

- Apply evenly to fully impregnate mesh fibers

- Recommended for use on drying lines or heated curing systems

- Avoid excessive material build-up to maintain flexibility

Suitable Stone Types

- Granite slabs

- Marble slabs

- Engineered stone and composite stone

Packaging & Supply

Available in standard industrial packaging. Custom packaging options are supported for bulk factory orders.

Direct supply from China manufacturer, suitable for OEM and long-term production contracts.

FAQ

Q1: Is this epoxy suitable for high-temperature summer workshops?

Yes. It is specifically formulated for summer conditions and drying-line production environments.

Q2: Does this product release strong odors during curing?

No. The system is designed to be odorless, improving operator comfort and workshop air quality.

Q3: Can it be used on automated mesh backing lines?

Yes. It is optimized for continuous production lines and oven-assisted curing systems.

For stone factories operating mesh backing lines in summer or high-temperature environments, 4090 / BCO25Q-14 offers a balanced solution combining odorless processing, stable curing, and reliable mesh adhesion—making it ideal for modern, high-efficiency production lines.