Low-Temperature Epoxy for Stone Mesh Backing & Slab Transport – 4090 / WBA25Q

Overview

Product Description

Low-temperature epoxy system designed for stone mesh backing applications, offering stable curing, reliable adhesion, and consistent slab reinforcement during winter operations and low ambient temperature processing.

Product Description

This epoxy resin system is specifically developed for stone mesh backing applications under low-temperature conditions. It delivers stable curing performance, reliable adhesion to mesh fabrics, and consistent slab reinforcement even when ambient temperatures are reduced. The system is particularly suitable for winter operations and slab transport processes where conventional epoxy systems may struggle to cure properly.

Engineered for industrial stone processing environments, the epoxy provides controlled viscosity for effective mesh impregnation while maintaining good workability and production efficiency.

Product Features & Specifications

| Feature | Description |

|---|---|

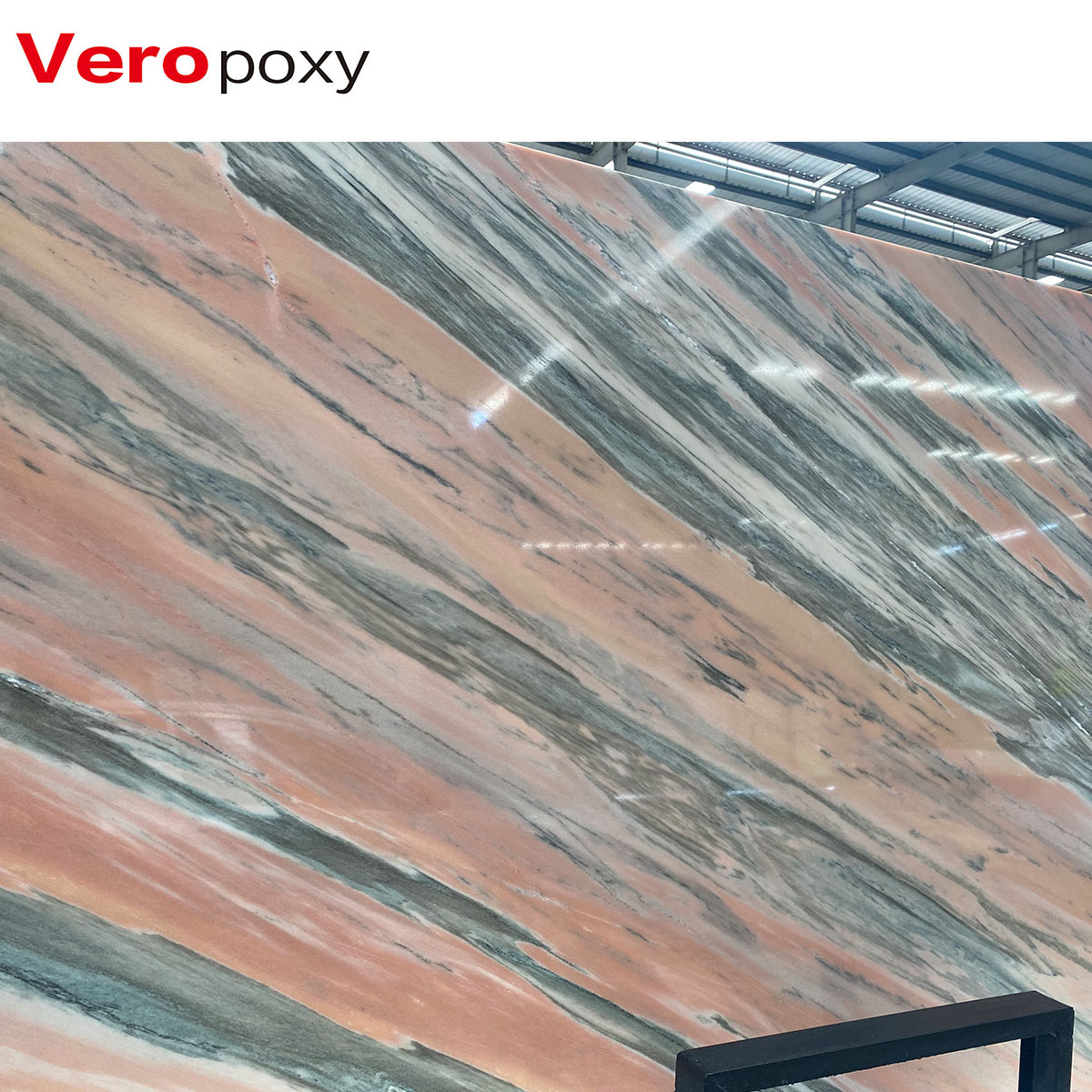

| Applicable Material | Natural stone slabs (granite, marble, engineered stone) |

| Epoxy System Code | 4090 / WBA25Q |

| Epoxy System Ratio | 100 : 25 |

| Durability | High stability and long-lasting performance after curing |

| Ease of Use | Easy to mix and apply, no special tools required |

| Curing Time | 50 minutes |

| Yellowing Resistance | Standard |

| Recommended Working Temperature | 10°C |

| Viscosity | 400–600 CPS |

Problems It Solves

- Poor curing performance of standard epoxy systems in low-temperature environments

- Insufficient mesh adhesion during winter mesh backing processes

- Slab instability during transport on carts in cold conditions

- Reduced production efficiency caused by slow or incomplete curing

Recommended Applications

- Stone mesh backing for slabs processed in cold or winter climates

- Reinforcement of slabs during transport on stone carts

- Manual or semi-automatic mesh backing production lines

- Industrial stone processing facilities with low-temperature operations

Key Performance Advantages

- Reliable curing behavior at low ambient temperatures

- Balanced viscosity for effective mesh penetration

- Stable mechanical performance after curing

- Designed for continuous industrial use

Product System Description

This epoxy system consists of a resin and hardener formulated specifically for low-temperature curing. The controlled reactivity ensures sufficient working time while achieving reliable strength development. Its formulation allows consistent impregnation of mesh fabrics without excessive flow or sagging.

Processing Suggestions

- Ensure stone surfaces are clean, dry, and free from dust before application

- Mix resin and hardener strictly according to the 100:25 ratio

- Apply evenly to achieve full mesh impregnation

- Maintain recommended ambient temperature during curing

- Provide basic ventilation during application due to slight odor

Suitable Stone Types

- Granite slabs

- Marble slabs

- Engineered stone

- Other natural stones requiring mesh backing reinforcement

Packaging & Supply

- Standard industrial packaging options available

- Suitable for bulk supply to stone processing factories

- Stable packaging for winter transportation and storage

FAQ

Is this epoxy suitable for winter conditions?

Yes. The system is designed to cure reliably at low temperatures around 10°C.

Can it be used for slab transport reinforcement?

Yes. It is suitable for mesh backing applications where slabs are transported on carts.

Does it require special equipment?

No. The epoxy is easy to mix and apply using standard tools.

What is the curing time?

The curing time is approximately 50 minutes under recommended conditions.

What types of stone are compatible?

Granite, marble, engineered stone, and other natural stone slabs.

This low-temperature mesh backing epoxy system provides a dependable solution for winter stone processing, ensuring consistent reinforcement quality and production stability when environmental conditions challenge conventional resin systems.