Long-Lasting Non-Yellowing Epoxy Resin for Hard White Marble – 5090 / D30M-BS

Overview

Product Description

This epoxy resin system is specifically designed for white marble applications, offering very low yellowing,

controlled penetration, and long-term color stability. It is ideal for high-end stone processing and

reinforcement where visual purity and durability are critical.

Product Description

This long-lasting non-yellowing epoxy resin system is specifically developed for hard white marble applications.

It delivers excellent color stability, very low yellowing performance, and durable reinforcement over time.

The system ensures controlled penetration without over-absorption, maintaining the natural purity and brightness

of white marble surfaces.

Product Features & Specifications

| Feature | Non-yellowing epoxy resin for hard white marble |

|---|---|

| Applicable Material | Hard White Marble |

| Epoxy System Code | 5090 / D30M-BS |

| Epoxy System Ratio | 100:30 |

| Durability | High stability and long-lasting performance after curing |

| Ease of Use | Easy to mix and apply, no special tools required |

| Curing Time | 80 minutes |

| Yellowing Resistance | Very low yellowing |

| Recommended Working Temperature | 24°C |

| Viscosity | 400–600 CPS |

Problems It Solves

- Yellowing issues commonly found in white marble epoxy applications

- Loss of surface brightness after long-term curing

- Insufficient durability in high-end white marble reinforcement

- Color instability under indoor temperature fluctuations

Recommended Applications

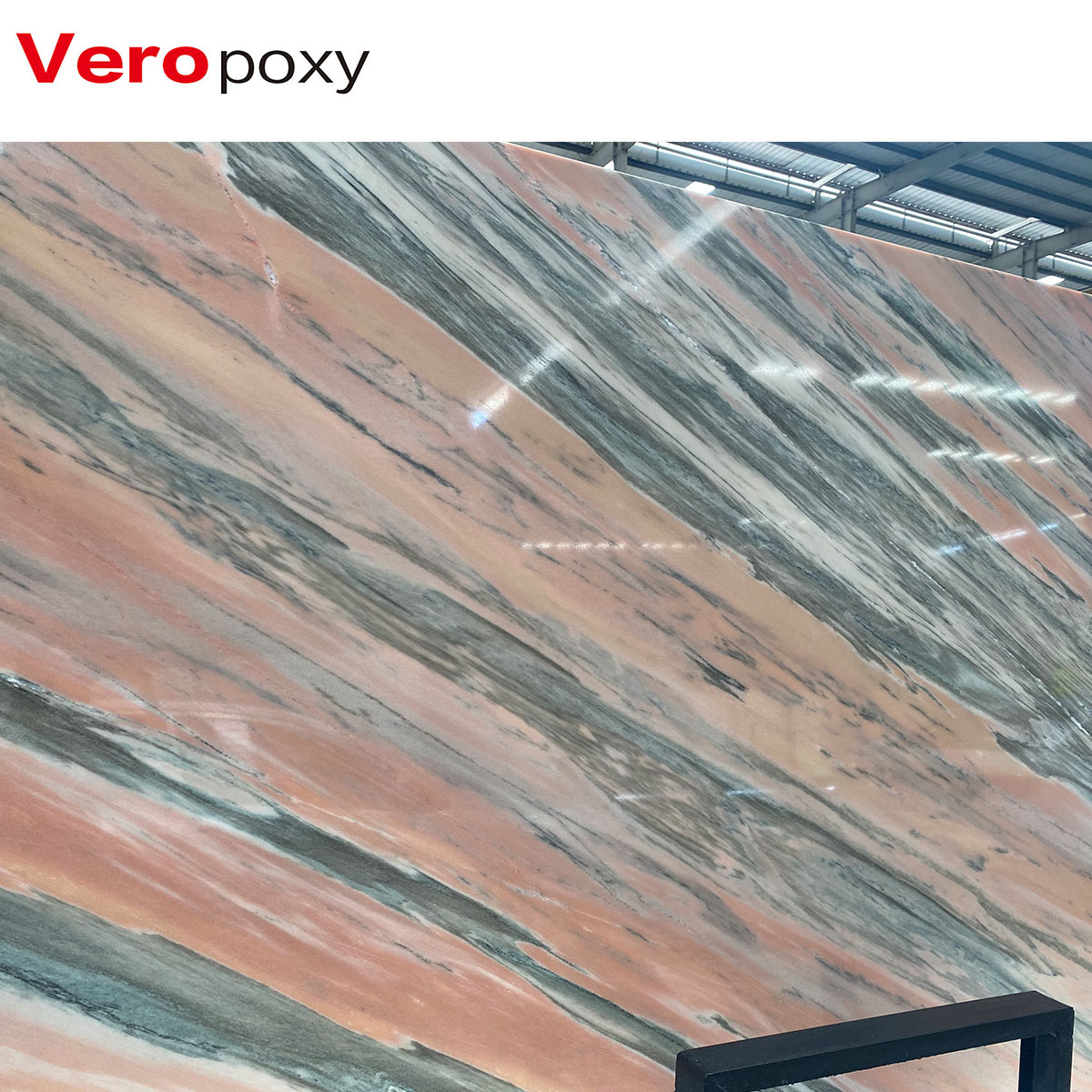

- Hard white marble slab repair and reinforcement

- High-end architectural white marble projects

- White marble surfaces requiring long-term color stability

- Factory and workshop resin treatment lines

Key Performance Advantages

- Very low yellowing for long-term aesthetic stability

- Excellent transparency and clarity after curing

- High resilience and mechanical stability over time

- Controlled penetration suitable for hard marble structures

Product System Description

This epoxy system combines an advanced resin formulation with a specially engineered hardener to ensure

extremely low yellowing and excellent long-term stability. The system is solvent-free and designed to

maintain consistent performance during curing and service life.

Processing Suggestions

- Ensure marble surface is clean, dry, and free of dust or contaminants

- Mix components accurately according to the specified ratio

- Apply evenly using brush, roller, or standard resin equipment

- Allow full curing under stable temperature conditions

Suitable Stone Types

- Hard white marble

- Dense crystalline marble structures

Packaging & Supply

Available in standard industrial packaging. Custom packaging and OEM solutions are available upon request.

Stable supply from manufacturer with support for bulk orders and long-term cooperation.

FAQ

Is this epoxy suitable for soft white marble?

This system is optimized for hard white marble. For soft marble, a dedicated low-penetration system is recommended.

Does the resin yellow over time?

No. The system is designed with very low yellowing characteristics to maintain long-term color stability.

Can it be used in automated production lines?

Yes. The viscosity and curing behavior are suitable for both manual and automated resin processing systems.

For white marble projects where long-term appearance matters, choosing a low-yellowing epoxy system

is critical. This product offers a balanced solution between penetration control, durability,

and visual preservation, making it a reliable choice for professional stone applications.