Deep Penetration Epoxy for Granite Repair – DF270-10 / BCO25Q

Overview

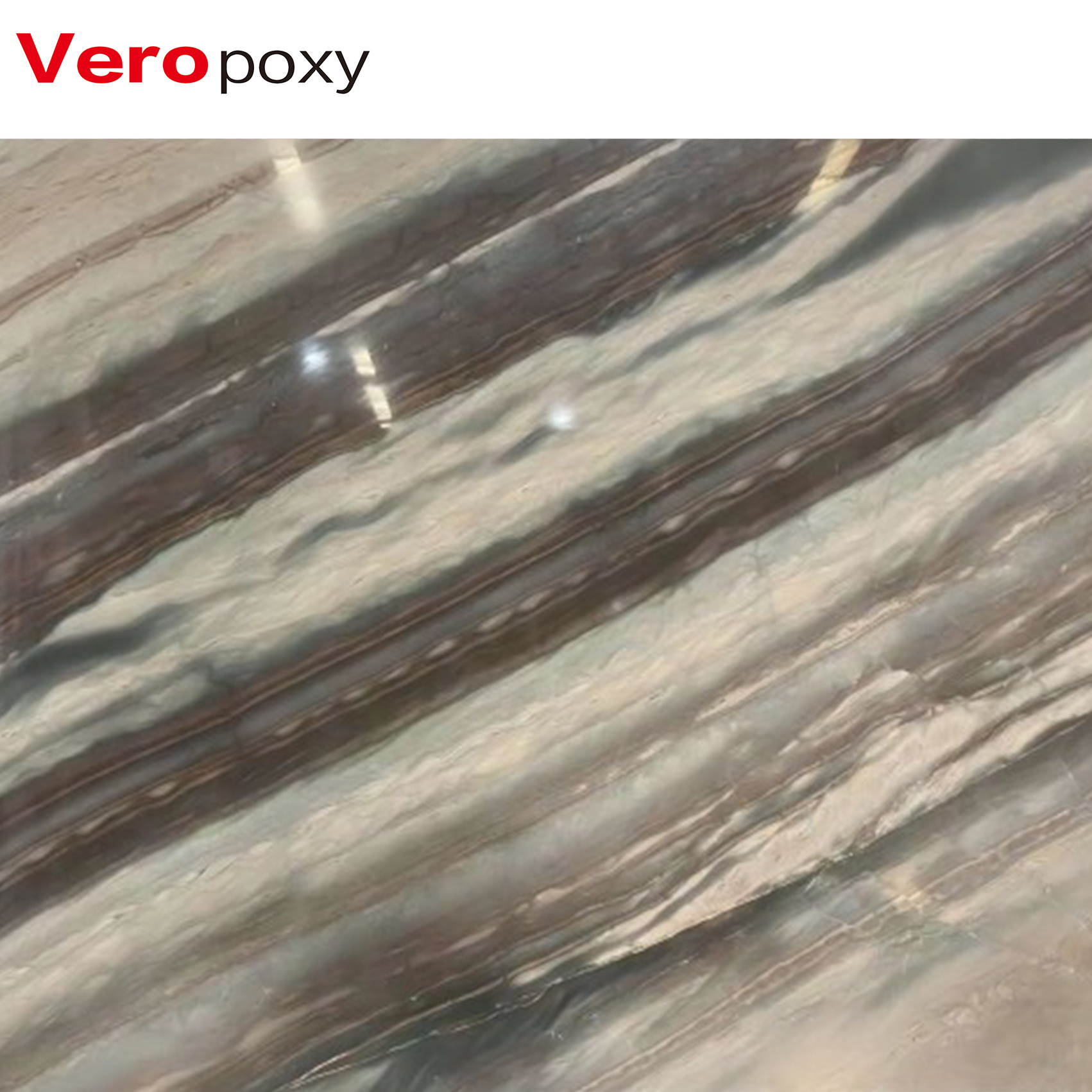

Deep Penetration Epoxy for Granite Repair DF270-10 / BCO25Q is an ultra-low viscosity epoxy system designed for deep impregnation into micro-cracks of granite, providing excellent wetting performance and strong internal bonding for black granite slabs.

Product Description

Deep Penetration Epoxy for Granite Repair DF270-10 / BCO25Q is an ultra-low viscosity epoxy system designed for deep impregnation into micro-cracks of granite, providing excellent wetting performance and strong internal bonding for black granite slabs.

Deep Penetration Epoxy for Granite Repair – DF270-10 / BCO25Q

Deep Penetration Epoxy for Granite Repair – DF270-10 / BCO25Q is a two-component epoxy resin system specially developed for repairing micro-cracks and internal fissures in granite. Its ultra-low viscosity allows the resin to penetrate deeply into dense stone structures, ensuring reliable internal reinforcement rather than surface-only repair.

Product Features & Specifications

| Feature | Description |

|---|---|

| Applicable Material | Granite |

| Epoxy System Code | DF270-10 / BCO25Q |

| Epoxy System Ratio | 100:25 |

| Durability | High stability and long-lasting after curing |

| Ease of Use | Easy to mix and apply, no special tools required |

| Curing Time | 24-48 hours |

| Yellowing Resistance | Normal |

| Temperature | 24°C |

| Viscosity | CPS 400-600 |

Problems It Solves

- Micro-cracks inside black granite slabs

- Poor resin penetration with conventional epoxy systems

- Weak internal bonding after granite crack repair

- Visible repair marks caused by insufficient wetting

Recommended Applications

- Black granite slabs with micro fissures

- Internal crack repair before polishing processes

- Deep impregnation treatment for dense granite

- Pre-reinforcement before surface finishing

Key Performance Advantages

- Deep Penetration Capability: Ultra-low viscosity enables deep penetration into micro-cracks and stone pores.

- Excellent Wetting Performance: Ensures full contact with the granite structure for improved bonding.

- Strong Internal Adhesion: Reinforces granite internally, enhancing overall slab strength.

- Stable Appearance After Curing: Suitable for black granite with minimal visual impact.

Product System Description

This product is a two-component epoxy resin system:

- Component A: DF270-10

- Component B: BCO25Q

Mixing ratio, pot life, and curing conditions are available upon request.

Processing Suggestions

- Clean cracks thoroughly and remove dust before application

- Apply epoxy by brushing, dripping, or injection methods

- Allow sufficient time for deep penetration before curing

- Proceed with polishing after full cure is achieved

Suitable Stone Types

- Black Granite

- Dense Granite with Micro Cracks

Packaging & Supply

- Standard A/B epoxy resin kits

- Custom packaging available upon request

- Factory direct supply with OEM / ODM support

DF270-10 / BCO25Q is ideal for granite manufacturers and stone processors seeking a reliable deep penetration epoxy solution to repair micro-cracks and reinforce black granite slabs from the inside, ensuring long-term structural stability.

Frequently Asked Questions

What is this epoxy resin mainly used for?

DF270-10 / BCO25Q is designed for deep penetration granite repair,

especially suitable for micro-cracks, fissures, and surface consolidation

of black granite slabs.

What is the mixing ratio of this epoxy system?

The recommended mixing ratio is 100:25 by weight (Component A : Component B).

Proper mixing ensures optimal penetration and curing performance.

How long does it take to cure?

The curing time is typically 24–48 hours at a working temperature of around 24°C.

Lower temperatures may extend the curing time.

Is this epoxy suitable for light-colored granite?

This product has normal yellowing resistance and is primarily recommended

for dark or black granite applications.

Can this epoxy be used before polishing?

Yes, it is commonly used before polishing to reinforce granite slabs,

fill micro-cracks, and improve overall slab stability.